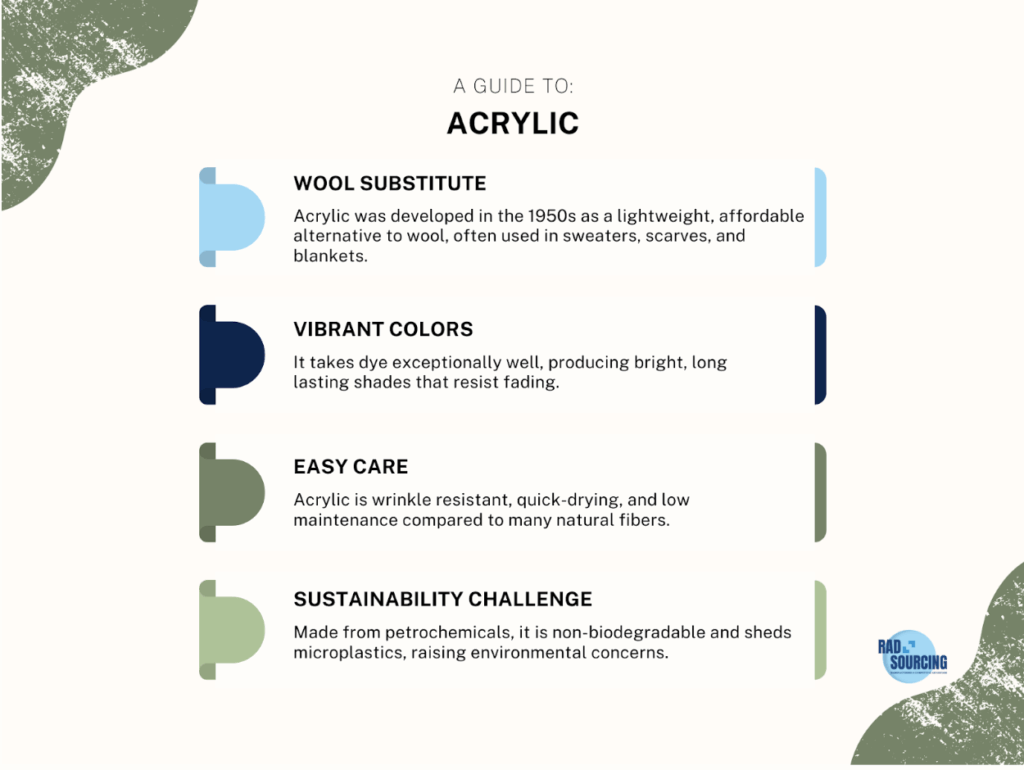

Acrylic is a synthetic fiber known for its wool-like feel, warmth, and affordability. It was first developed in the 1940s by the DuPont Company, the same firm that developed nylon and polyester. Commercial production of acrylic fibers began in the 1950s, and the material quickly gained popularity as a substitute for wool due to its softness, resilience, and ease of care. By the mid-20th century, acrylic sweaters, blankets, and outerwear were widespread, offering consumers a cost-effective alternative to natural fibers.

Chemically, acrylic is a polymer made from acrylonitrile, a petroleum-derived compound. To produce acrylic fiber, acrylonitrile is polymerized with other monomers to improve dyeability and performance. The resulting polymer solution is then extruded through spinnerets into a coagulating bath (wet spinning) or evaporated in a chamber (dry spinning), where it solidifies into long filaments. These filaments are then stretched, washed, cut into staple lengths, and spun into yarns. Depending on the spinning and finishing methods, acrylic fibers can be made to resemble wool, cotton, or even cashmere

Acrylic’s key properties have ensured its continued popularity. It is lightweight, soft, and warm, with a texture that mimics wool and is hypoallergenic, as well as resistant to moths. Acrylic is easy to dye, allowing for vibrant, long-lasting colors. It resists wrinkles, shrinkage, and mildew, and it dries quickly, making it a low-maintenance fiber for everyday use. However, acrylic is less breathable than natural fibers and can sometimes feel less comfortable in warm climates.

Due to its wool-like qualities, acrylic is widely used in sweaters, scarves, hats, and socks. It is also common in blankets, upholstery fabrics, and rugs. When blended with other fibers, such as wool, cotton, or polyester, acrylic enhances softness, durability, and affordability. Specialty forms, such as modacrylic, are used in flame-resistant clothing, wigs, and faux furs due to their unique performance characteristics.

From a sustainability perspective, acrylic poses significant challenges. It is made from petrochemicals, which depend on non-renewable fossil fuels. Its production process involves toxic substances such as acrylonitrile, which can be hazardous to workers and the environment if not carefully controlled. Acrylic is also non-biodegradable and contributes to microplastic pollution when washed, shedding fibers that persist in waterways and oceans. Furthermore, its energy-intensive production adds to its environmental footprint.

While recycling acrylic is technically possible, it remains uncommon due to the complexity of separating and reprocessing the fibers. Some initiatives are exploring chemical recycling of acrylic and the use of bio-based acrylonitrile to reduce dependence on fossil fuels. Certifications such as OEKO-TEX can indicate safer production practices, but large-scale sustainable solutions for acrylic remain limited.

Despite these drawbacks, acrylic remains valued for its affordability and versatility. It provides consumers with accessible warmth and style, often at a fraction of the cost of wool or cashmere. For many, it is a practical choice that balances fashion and budget, though its environmental costs are increasingly scrutinized in the context of sustainable fashion.

Acrylic demonstrates both the benefits and the costs of synthetic innovation. While it democratized access to soft, warm clothing, its environmental impact underscores the need for continued research into sustainable alternatives and responsible consumption practices.