Bamboo has emerged as a popular textile fiber in the 21st century, celebrated for its association with sustainability, softness, and natural origin. While bamboo has been used for centuries in Asia as a building material, paper, and traditional clothing, its development into modern textile fibers is a relatively recent phenomenon. Bamboo fabrics began entering mainstream fashion and home textiles in the early 2000s, marketed as an eco-friendly alternative to cotton and synthetic fibers.

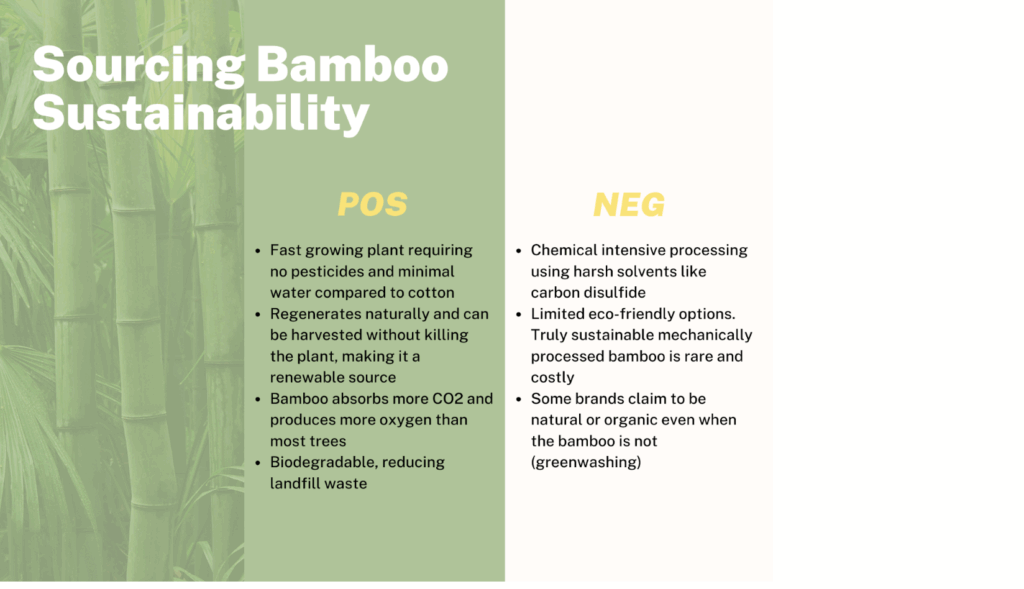

Bamboo textiles are derived from the cellulose of bamboo plants, which are among the fastest-growing plants on Earth. Certain species can grow up to a meter in a single day, making bamboo a highly renewable resource. The plant requires little irrigation, no pesticides, and regenerates after harvesting, giving it strong sustainability credentials at the raw material stage.

There are two primary methods of making bamboo textiles: mechanical and chemical. Mechanically processed bamboo linen is made by crushing the woody parts of the bamboo plant, using natural enzymes to break down the fibers, and then combing them into threads. This method produces a fabric similar to linen, which is strong and textured; however, it is labor-intensive and costly, making it rare on the market. The more common method is chemical processing, in which bamboo cellulose is dissolved using solvents such as sodium hydroxide and carbon disulfide, then extruded into fibers much like viscose. This results in a fabric often labeled as “bamboo rayon” or “viscose from bamboo.” While soft and silky, this process is chemically intensive and raises environmental and health concerns when not managed responsibly.

The resulting bamboo fabrics are prized for their softness, breathability, and moisture-wicking properties. They feel cool to the touch, making them especially popular for summer apparel, underwear, socks, and bed linens. Bamboo fabric is also naturally hypoallergenic and has been promoted for its antibacterial properties; however, research suggests that this benefit may be reduced after processing. Still, bamboo fabrics offer a smooth, luxurious feel, while remaining affordable and versatile.

From a sustainability perspective, bamboo’s story is more complex. While the plant itself is highly renewable and requires fewer agricultural inputs than cotton, the chemical processing of bamboo into viscose can offset these benefits if not handled in a closed-loop system. Facilities that release untreated chemicals into the environment contribute to pollution and occupational hazards. On the other hand, when bamboo is processed in closed-loop systems similar to those used for lyocell (sometimes marketed as bamboo lyocell), the environmental impact is significantly reduced. Certifications such as OEKO-TEX and FSC can help consumers identify bamboo products made to higher environmental standards.

Geographically, bamboo textiles are primarily produced in China, which has abundant bamboo resources and a well-developed infrastructure for viscose production. Smaller operations exist in other parts of Asia, but China remains the dominant player in bamboo fabric production.

Bamboo textiles are used in a wide range of products, including clothing such as T-shirts, leggings, and underwear, as well as household goods like towels, sheets, and blankets. Their breathability and softness also make them popular for baby clothing and swaddles. Blending bamboo with other fibers, such as cotton or elastane, can enhance strength and stretch while maintaining comfort.

Bamboo fabrics reflect both the promise and complexity of sustainable textiles. While bamboo cultivation is inherently eco-friendly, the processing method determines the true environmental footprint. As closed-loop technologies expand and consumer awareness grows, bamboo has the potential to become a cornerstone of sustainable fashion and home goods.