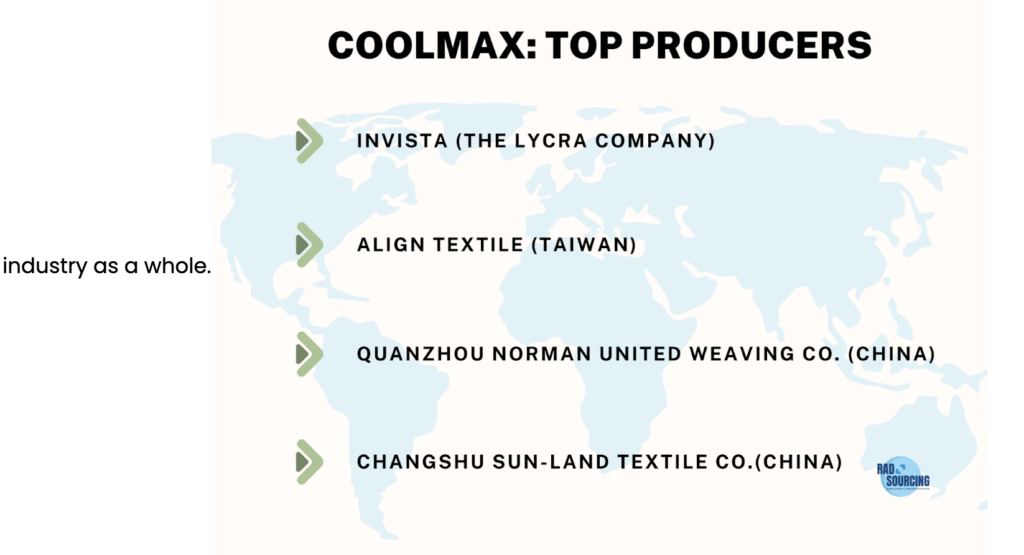

Coolmax is a high-performance fabric engineered to enhance moisture management and comfort, particularly during physical activity. Developed in 1986 by DuPont (the same company that created nylon, polyester, and spandex), Coolmax was designed as a technical alternative to cotton and other natural fibers, which tend to retain moisture. Today, Coolmax is a registered trademark owned by The LYCRA Company, and it remains a leading fabric technology in sportswear, outdoor gear, and active apparel.

Unlike many fibers that rely solely on chemical treatments, Coolmax’s performance comes from its specially engineered fiber shape. The fabric is made from polyester fibers extruded with a unique cross-sectional design, often featuring channels or grooves that increase surface area. This structure enhances the fiber’s ability to wick moisture away from the skin by capillary action, spreading sweat across a wider area so it can evaporate more quickly. The result is a fabric that keeps the wearer dry, calm, and comfortable, even in high-intensity or hot environments.

Coolmax fabrics are lightweight, breathable, and quick-drying. Because the moisture-wicking properties are built into the fiber’s structure rather than applied as a finish, they do not wash out or degrade with repeated laundering. In addition to moisture management, Coolmax fabrics are soft against the skin and durable, making them suitable for both everyday wear and specialized sports gear. Variants of Coolmax, such as Coolmax All Season or Coolmax EcoMade, expand its applications by combining performance with insulation or sustainability.

Coolmax production relies on advanced polyester extrusion processes. The polyester used may be virgin or recycled, depending on the product line. Coolmax EcoMade, for example, incorporates polyester derived from recycled PET bottles, reducing reliance on virgin petrochemicals. After extrusion, the fibers are spun into yarns, which are then knitted or woven into fabrics designed for specific end uses, from lightweight mesh for running shirts to denser weaves for socks and base layers.

From a sustainability perspective, Coolmax shares both the advantages and drawbacks of polyester. On the one hand, it is highly durable, requires less water and energy for laundering than cotton, and EcoMade options divert plastic bottles from landfills. On the other hand, Coolmax is still a synthetic, petroleum-derived fiber that is non-biodegradable and contributes to microplastic pollution during washing. While recycling initiatives help mitigate some of these issues, the environmental impact of synthetic performance fibers remains a significant challenge for the industry as a whole.

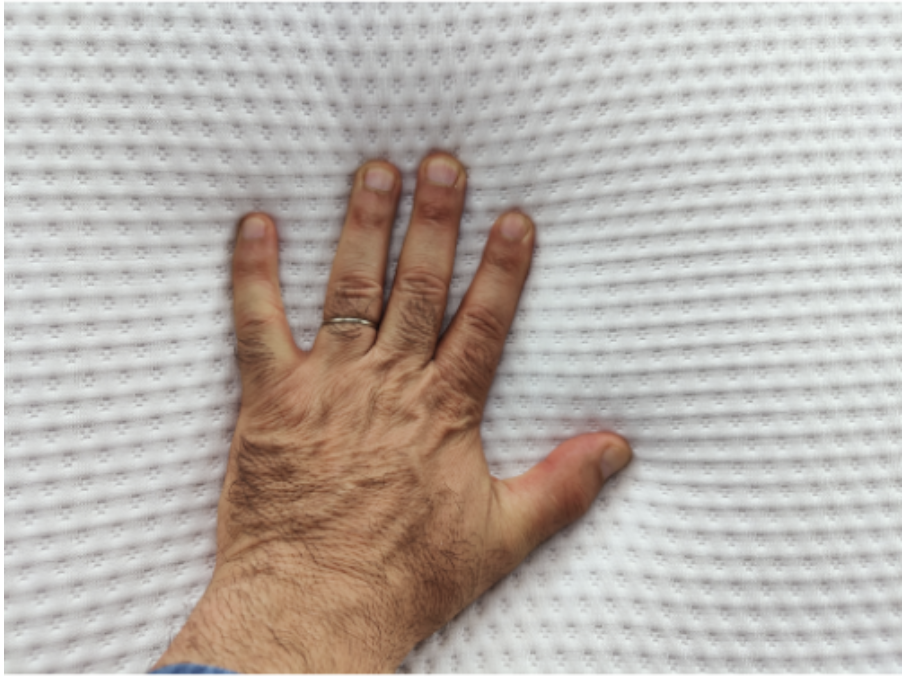

Coolmax is widely used in sports and activewear, where moisture management is crucial. Running shirts, cycling jerseys, yoga wear, and hiking gear often incorporate Coolmax to keep athletes dry and comfortable. It is also common in socks, underwear, and base layers that benefit from enhanced breathability. Beyond activewear, Coolmax is also found in casual apparel, workwear, and even bedding, such as sheets and mattress covers, which are marketed for their cooling and moisture-wicking properties.

Coolmax represents a milestone in functional textile innovation, combining science and design to solve the challenges of sweat and heat management. Its evolution into sustainable variants, such as Coolmax EcoMade, demonstrates how performance fabrics can adapt to meet the demands of both athletes and eco-conscious consumers, thereby securing their place as go-to fabrics in modern performance apparel.