Hemp is one of the world’s oldest cultivated fibers, with evidence of its use dating back over 8,000 years in regions such as China and the Middle East. Historically, hemp has been prized for its strength, versatility, and abundance. It was widely used for ropes, sails, paper, and clothing, and in many cultures, hemp textiles were a staple long before cotton rose to dominance. In the modern era, hemp is experiencing a revival as a sustainable alternative to conventional fibers, offering durability, comfort, and a significantly lighter environmental footprint.

Hemp fiber is derived from the stalk of the Cannabis sativa plant, specifically from the bast fibers located in the outer layer of the stem. Unlike its psychoactive cousin marijuana, industrial hemp varieties are cultivated to contain negligible amounts of THC and are grown primarily for their fiber, seeds, and oil. Once harvested, the stalks undergo a process called retting, in which natural moisture or water is used to break down the pectins that bind the fibers to the woody core. The separated fibers are then dried, carded, and spun into yarns for weaving or knitting.

Hemp fibers are long, strong, and naturally resistant to mold, UV light, and pests. They are breathable and moisture-absorbent, making hemp textiles comfortable to wear in warm weather. With repeated washing, hemp fabrics become softer without losing strength. Hemp can be woven into coarse, durable fabrics suitable for workwear or into finer, softer textiles that resemble linen. When blended with cotton or other fibers, hemp combines durability with added softness and flexibility.

Hemp cultivation is significantly more sustainable than many other natural fibers. The plant grows rapidly, reaching up to four meters in just three months, and requires minimal to no pesticides or herbicides. Hemp uses far less water than cotton and improves soil health through its deep root systems, which reduce erosion and promote soil aeration. Additionally, hemp cultivation absorbs large amounts of carbon dioxide, making it one of the most climate-friendly crops available.

Despite these advantages, hemp textiles face some challenges. Processing hemp fibers into soft, apparel-grade fabrics can be more labor-intensive than processing cotton, and in many regions, the infrastructure for large-scale hemp textile production is still limited. For decades, restrictive laws on cannabis cultivation also hindered hemp’s development as a mainstream textile fiber. However, recent policy changes in countries like the United States and increased global demand for sustainable materials are revitalizing the hemp industry.

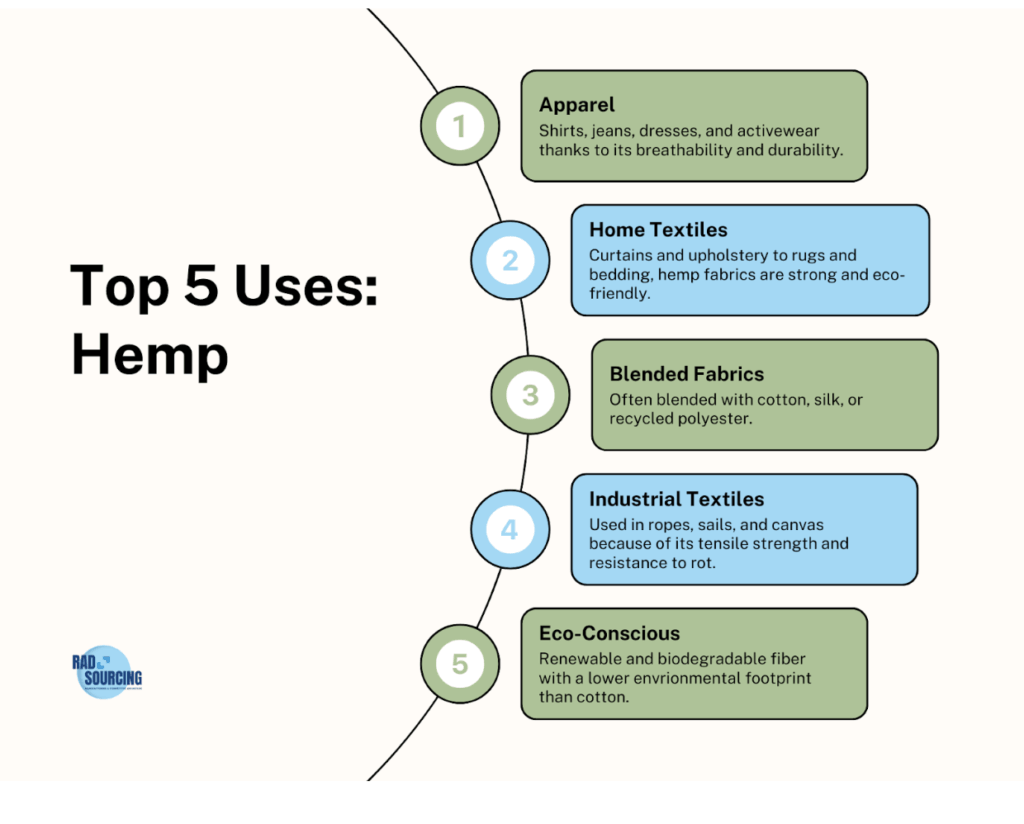

Hemp fabrics are used in a wide range of products, including casual apparel such as T-shirts, jeans, and dresses, as well as accessories, shoes, and home textiles like curtains, upholstery, and rugs. Blends of hemp with cotton, silk, or even recycled polyester are increasingly common, combining hemp’s durability with the softness or performance of other fibers. Hemp is also popular in eco-conscious fashion collections and outdoor apparel, where its natural performance properties align with sustainability values.

From a sustainability perspective, hemp offers distinct advantages over conventional cotton and many synthetic materials. It is renewable, biodegradable, and low in water and chemical inputs. However, to fully realize its potential, investment in processing technology and global supply chains is needed to make hemp textiles more accessible and affordable for mass-market use. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can help consumers identify responsibly produced hemp textiles.

Hemp embodies both tradition and innovation, standing as one of the most promising fibers for a sustainable future. With its deep historical roots, versatile applications, and eco-friendly cultivation, hemp has the potential to redefine modern textiles as consumers and industries seek high-performing, environmentally responsible fibers.