Lycra is the brand name of a highly elastic synthetic fiber, known generically as spandex in the United States and elastane elsewhere. It was invented in 1958 by chemist Joseph Shivers at DuPont as a superior alternative to rubber in the textile industry. The introduction of Lycra transformed the fashion and performance apparel industries, allowing garments to become more flexible, body-hugging, and durable without compromising comfort.

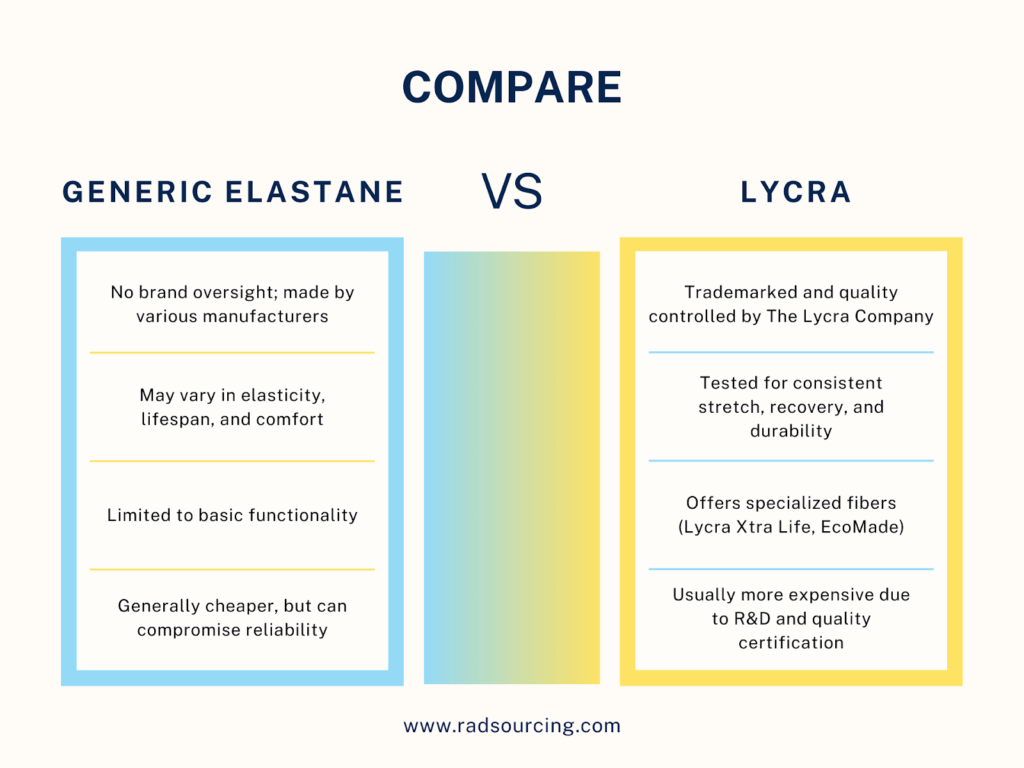

What differentiates Lycra from generic elastane is its brand pedigree and strict quality standards. The LYCRA Company licenses the brand to textile mills that meet specific manufacturing requirements, ensuring consistent fiber performance across garments. As a result, the name “Lycra” has become synonymous with high-quality stretch in activewear, swimwear, underwear, hosiery, and denim.

Lycra is made using a solution-dry spinning process, which begins with the preparation of a prepolymer by combining a diisocyanate with a macroglycol. This prepolymer is then reacted with a diamine chain extender to form a stretchy, elastic polymer. The polymer solution is pushed through spinnerets to create fine filaments, which are cured and treated with finishing agents to enhance blendability and durability. These fibers are then wound into spools and shipped to mills where they are blended with cotton, polyester, or nylon to produce stretch fabrics.

The result is a fiber that can stretch up to 600% and recover to its original shape. Lycra is valued for its lightweight, smooth texture, and ability to move with the body. It resists perspiration, body oils, and UV exposure better than rubber-based stretch fibers. In garments, it provides improved fit, freedom of movement, and shape retention. Because it is used in such small quantities (typically 2–5%), it enhances garment performance without dominating their texture or aesthetic.

From lingerie to leggings, Lycra is ubiquitous in modern fashion. In athletic wear, it helps prevent fabric sagging and bunching during movement. In swimwear, it withstands exposure to chlorine and saltwater. Denim allows jeans to hug the body while maintaining comfort. Hosiery and shapewear benefit from Lycra’s superior elasticity, providing support without constriction.

Lycra’s environmental footprint is comparable to that of other petroleum-based synthetics. It is derived from fossil fuels and requires the use of solvents and other chemicals during its manufacturing process. Like other elastane fibers, it is not biodegradable and can complicate recycling efforts when blended with natural fibers. However, the LYCRA Company has taken steps to address these issues. It has introduced partially recycled elastane options (such as LYCRA® EcoMade) that incorporate pre-consumer waste and aim to reduce the carbon footprint of stretch textiles.

The company also partners with sustainable fashion initiatives and certifications, such as OEKO-TEX and Bluesign, to ensure safer production practices. While Lycra is still a synthetic material with inherent sustainability limitations, efforts to improve its production and lifecycle management are underway. Responsible consumers can look for garments made with certified recycled Lycra or those carrying trusted eco-labels.

Lycra revolutionized modern fashion by introducing comfort-driven stretch to everyday clothing. Though small in percentage within fabrics, its impact on fit, function, and freedom of movement is immense. As brands and consumers push for greater sustainability, Lycra’s future lies in responsible innovation that blends performance with environmental stewardship.