Lyocell is a semi-synthetic fiber that represents a significant step forward in sustainable textile innovation. First developed in the late 20th century, Lyocell was introduced as a more environmentally friendly alternative to traditional viscose and modal fibers. The most recognized Lyocell brand today is TENCEL, produced by the Austrian company Lenzing AG, which brought the fiber to the commercial market in the 1990s.

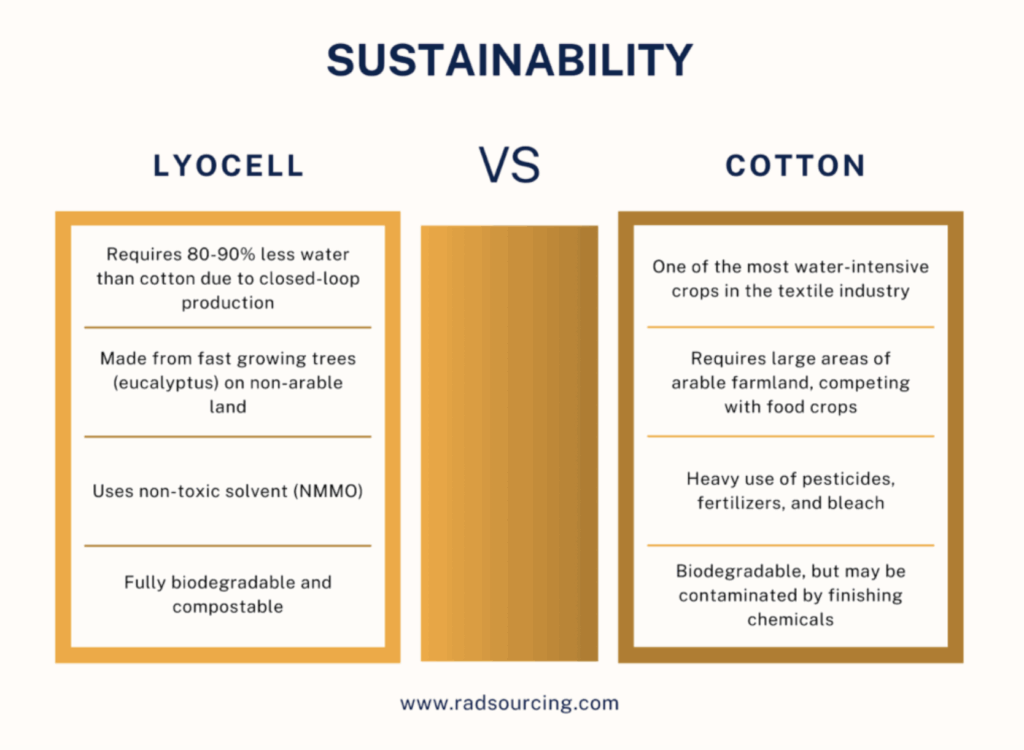

What makes Lyocell distinct is its eco-conscious production process and its ability to blend the softness and breathability of natural fibers with the performance advantages of synthetics. Lyocell is derived from cellulose, typically harvested from sustainably grown trees such as eucalyptus, beech, or spruce. Unlike viscose, which uses carbon disulfide and other hazardous chemicals, Lyocell is manufactured in a closed-loop process that uses a non-toxic, recyclable solvent, N-methylmorpholine N-oxide (NMMO). This process reclaims and reuses over 99% of the solvent, significantly reducing water pollution and chemical waste.

The production begins with wood pulp, which is broken down into a slurry and mixed with NMMO to create a clear, viscous solution. This solution is then extruded through fine spinnerets into a water bath, where it solidifies into fibers. After washing and drying, the fibers are ready to be spun into yarn. Because the source wood is often harvested from Forest Stewardship Council (FSC)-certified plantations, and because the manufacturing process minimizes emissions and water use, Lyocell is widely regarded as one of the most sustainable commercially available fibers.

Lyocell fabric boasts a silky, smooth texture and is renowned for its breathability, moisture-wicking properties, and natural resistance to wrinkles and bacteria. It is also strong both in wet and dry conditions, making it highly durable. These qualities make it ideal for a wide range of applications, including casual and formal wear, activewear, bed linens, towels, and even denim blends. Due to its versatility and comfort, Lyocell is often used in garments that are worn directly against the skin.

From a sustainability perspective, Lyocell has numerous advantages. The use of fast-growing, low-water-demand trees, such as eucalyptus, reduces the burden on land and water resources. The closed-loop solvent system significantly reduces harmful emissions, and the resulting fibers are biodegradable under industrial composting conditions. Unlike synthetic fibers, Lyocell does not shed microplastics and can break down more easily in the environment. Furthermore, because it dyes well and holds color, Lyocell often requires fewer dyeing agents than conventional cotton or polyester, contributing to a lower environmental impact in the finishing stages.

However, it’s worth noting that not all Lyocell on the market is equal. Some manufacturers may deviate from the closed-loop model or source wood from non-sustainable forestry operations. As with viscose, the presence of a recognized certification, such as TENCEL, FSC, or OEKO-TEX, can help consumers identify genuinely sustainable Lyocell textiles.

In terms of challenges, Lyocell is more expensive to produce than many conventional fibers, which can lead to higher retail prices for finished garments. Additionally, while the fiber itself is sustainable, blending it with less eco-friendly fibers, such as polyester, may compromise its recyclability and biodegradability.

Lyocell exemplifies how modern textile science can create materials that are both high-performing and environmentally responsible. As more brands commit to greener practices, Lyocell is poised to become a cornerstone of sustainable fashion and interior design.