Micromodal is a premium semi-synthetic fiber known for its silky softness, breathability, and lightweight drape. It is a finer version of modal, which itself is a type of rayon derived from cellulose. Both fibers are produced using the same fundamental process; however, Micromodal utilizes thinner filaments to create a fabric that is even softer and more luxurious, feeling similar to silk or high-end cotton.

Modal was first developed in Japan in the 1950s, but the refinement known as Micromodal was pioneered in the 1990s by Lenzing AG, an Austrian company recognized for its sustainable cellulose-based textiles. Since then, Micromodal has gained popularity in premium underwear, loungewear, sleepwear, and other garments worn close to the skin.

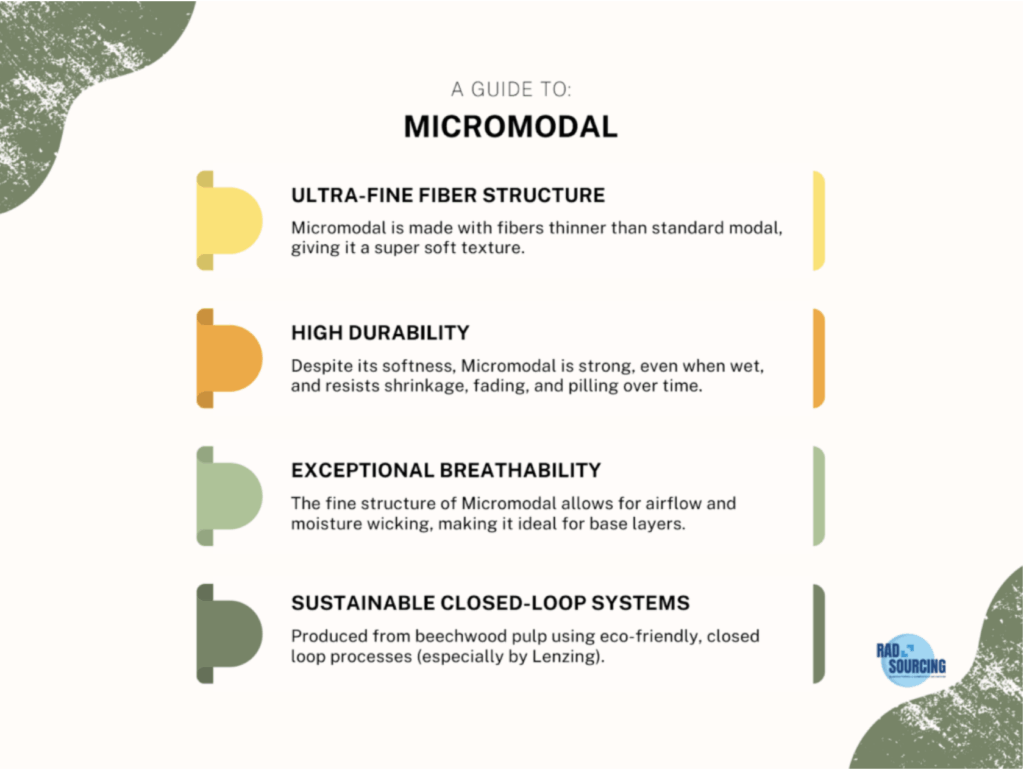

The production of Micromodal begins with sustainably harvested beechwood, usually sourced from FSC- or PEFC-certified forests. The wood is chipped and pulped, then treated in a closed-loop system that converts the cellulose into a viscous liquid using environmentally safer solvents. This liquid is extruded through spinnerets to form ultra-fine fibers, which are then spun into yarns and woven or knit into fabrics. What sets Micromodal apart from regular modal is its extra-fine fiber size, which enhances the fabric’s softness, breathability, and overall comfort.

Micromodal fabrics are prized for their gentle touch against the skin. They are not only incredibly soft but also lightweight, breathable, and highly absorbent, making them ideal for intimate apparel. The fibers are strong even when wet, and they retain their shape and color through repeated washes. Additionally, Micromodal resists pilling and shrinkage better than many other cellulosic or cotton-based textiles.

The fabric also holds dye exceptionally well, which contributes to its vivid, long-lasting color. These performance characteristics have made Micromodal popular in high-quality men’s and women’s underwear, base layers, leggings, T-shirts, and pajamas. The fine texture makes it feel cool and smooth, enhancing its comfort in both warm and cold climates.

From a sustainability perspective, Micromodal has several advantages. The raw material, beechwood, is renewable and often harvested from sustainably managed European forests. The closed-loop process used by Lenzing recycles water and over 95% of the chemicals involved, resulting in a significantly reduced environmental impact compared to conventional viscose production. Micromodal is also biodegradable and compostable under industrial conditions, providing a superior end-of-life profile compared to synthetic fibers.

That said, not all modal or micromodal products are produced with the same environmental standards. Some suppliers may not use certified wood or closed-loop systems, so consumers are encouraged to look for certifications such as TENCEL™ Modal, OEKO-TEX Standard 100, or FSC to ensure the fiber’s environmental integrity. Products labeled “Micromodal Air” or “TENCEL™ Micromodal” generally come from Lenzing and are among the most sustainable options available.

While Micromodal tends to be more expensive than cotton or standard rayon, its long lifespan and luxurious comfort make it a worthwhile investment for many consumers. It also pairs well with elastane to provide stretch without compromising breathability. As a result, many premium brands use Micromodal in blends that enhance softness, flexibility, and durability.

Micromodal represents a fusion of luxury and environmental consideration, a textile that elevates everyday garments while supporting more sustainable sourcing and manufacturing practices. As consumers continue to seek comfort without compromise, Micromodal is positioned to remain a key player in the evolution of conscious fashion.