Sympatex is a high-performance, waterproof, windproof, and breathable membrane used in outdoor apparel, footwear, and technical textiles. Developed in 1986 by Sympatex Technologies GmbH in Germany, the material is best known as a non-porous, recyclable alternative to PTFE-based membranes, such as Gore-Tex. Unlike traditional microporous membranes, Sympatex functions through hydrophilic molecular diffusion, offering both environmental responsibility and exceptional comfort. It has become a benchmark in sustainable performance fabrics, combining technical innovation with circular design principles.

The core of Sympatex lies in its co-polyether–ester membrane, which is completely free of polytetrafluoroethylene (PTFE) and perfluorinated compounds (PFCs). These substances, common in other waterproof membranes, are persistent environmental pollutants. Sympatex’s innovation was to create a non-porous, hydrophilic membrane that uses chemical properties rather than physical pores to manage moisture. This structure allows water vapor (sweat) to pass outward while blocking liquid water and wind from entering, thereby maintaining comfort even during intense physical activity or extreme weather conditions.

Sympatex’s functionality is based on molecular transport. The membrane contains hydrophilic (water-attracting) elements that absorb moisture vapor from inside the garment and release it to the outside through molecular diffusion. The higher the body temperature or humidity, the faster the transfer, making the membrane “smart” and self-regulating. This dynamic process ensures consistent breathability, waterproofing, and wind protection, without relying on microscopic pores that can clog or degrade over time.

Sympatex membranes are extremely thin, measuring only 5 to 25 microns, and are typically laminated to fabrics such as polyester, polyamide, or recycled synthetic materials. The finished textile is 100% waterproof (with a water column of over 45,000 mm), 100% windproof, and 100% breathable, offering comfort and protection across diverse environments. In addition, the membrane remains elastic and lightweight, maintaining flexibility for activewear, outdoor gear, and footwear.

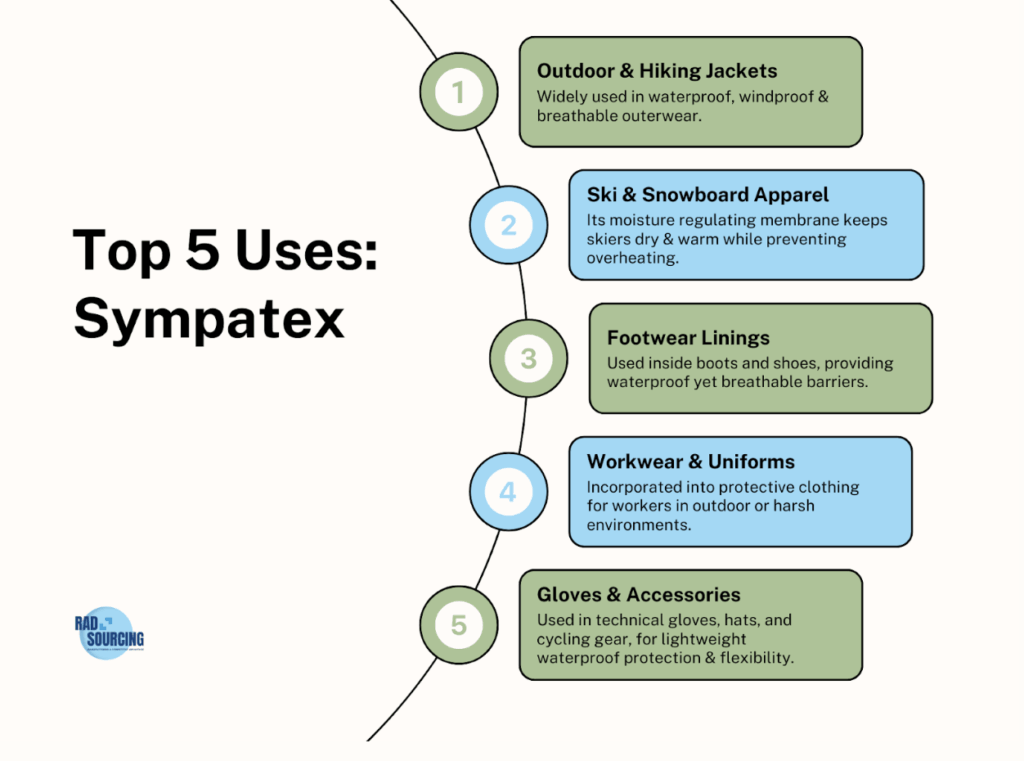

Sympatex’s properties make it ideal for performance-oriented applications.

- Waterproof & Windproof: Prevents any water penetration, even under pressure, while blocking wind chill.

- Breathable & Thermoregulating: Adapts to activity level, allowing sweat vapor to escape efficiently.

- Durable & Easy-Care: Resistant to washing, abrasion, and temperature fluctuations.

- Eco-Friendly: Fully recyclable, free from harmful fluorocarbons, and certified under environmental standards such as bluesign®, OEKO-TEX®, and ClimatePartner.

Sympatex is widely used in outdoor apparel, ski wear, hiking boots, gloves, and medical textiles, as well as in industrial protective gear. Leading outdoor brands, such as Vaude, Mammut, Schöffel, and Patagonia (in select lines), use Sympatex laminates for their sustainable, high-performance collections. In footwear, the membrane is applied as a lining to create waterproof yet breathable shoes suitable for trekking or urban use.

From a sustainability perspective, Sympatex stands out among technical fabrics. Unlike many waterproof membranes, it is fully recyclable and designed to be reprocessed into new functional membranes within a closed-loop system. Its raw materials are derived partly from recycled PET bottles, reducing dependence on virgin plastics. Moreover, its production is carbon neutral, and the company offsets unavoidable emissions through certified climate projects. Sympatex also avoids PFC-based durable water repellents (DWRs) and instead relies on water-based, biodegradable alternatives.

The company’s philosophy, summed up in the motto “guaranteed green,” positions Sympatex as a pioneer in environmentally responsible performance textiles. In addition to circular production, the brand participates in initiatives to enhance the recyclability of garments at the end of their life, collaborating with organizations and other brands to close the textile recycling loop. By enabling the creation of monomaterial garments (e.g., 100% polyester layers bonded to a polyester membrane), Sympatex makes full textile recycling feasible, an innovation that significantly reduces waste in outdoor apparel.

Sympatex membranes are produced and laminated primarily in Germany, Austria, and other European facilities, ensuring strict environmental oversight and quality control. This European production model supports both high performance and traceability, both of which are increasing priorities for sustainable supply chains.

Sympatex represents a new generation of eco-engineered performance fabrics, proof that technical innovation and environmental responsibility can go hand in hand. Combining cutting-edge waterproofing with circular design, it challenges the notion that high performance requires ecological compromise. As outdoor and fashion industries push toward carbon neutrality and material circularity, Sympatex stands as a model for what sustainable technology can achieve: protection for both people and the planet.