Banana fabric is a natural, plant-based textile made from the fibers of the banana plant (Musa species). Sometimes called banana silk or banana fiber fabric, it is celebrated for its sustainability, strength, and silky texture. Long before the rise of industrial textiles, banana fibers were used across Asia to make traditional garments and ropes. Today, this ancient material is being revived as an eco-friendly alternative to cotton, silk, and synthetic fibers.

The origins of banana fabric date back centuries, particularly in Japan, Nepal, and the Philippines, where artisans processed banana fibers by hand to make fine clothing and household textiles. In Japan, banana fiber textiles, known as bashō-fu, were historically woven into kimonos and ceremonial garments. In the Philippines, banana fiber, known as abacá, has become an important export material for ropes, mats, and specialty papers. The recent global emphasis on sustainable fashion has renewed interest in banana fabric as a biodegradable, renewable textile with minimal environmental impact.

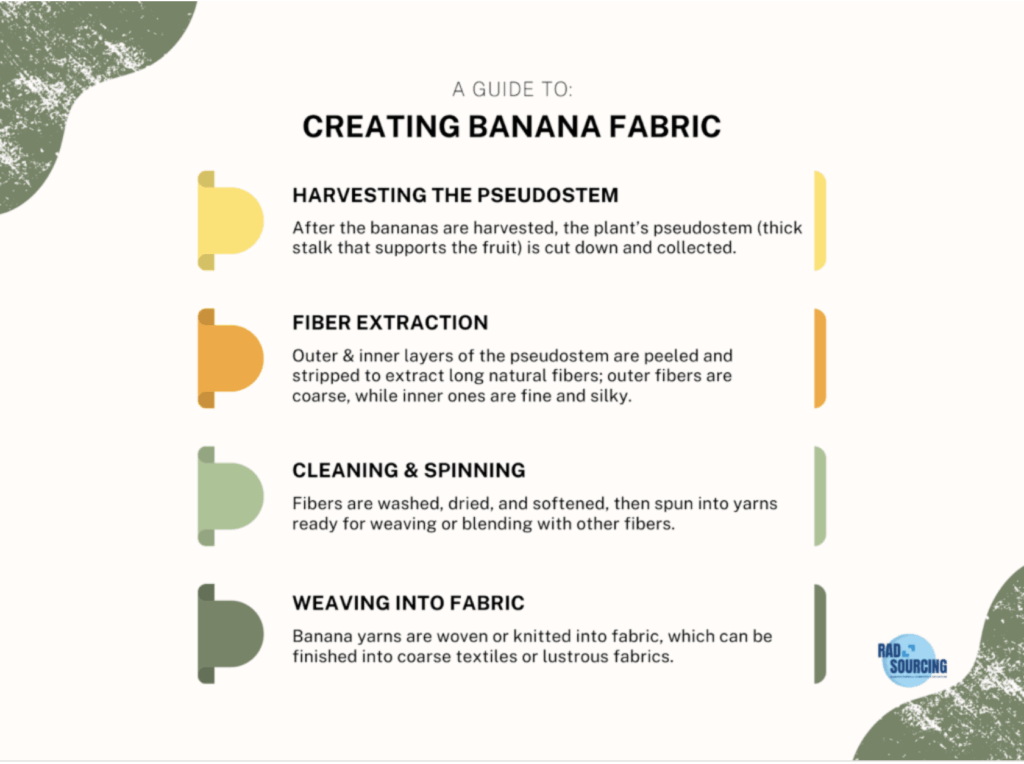

The production of banana fabric begins with the banana plant’s pseudostem, which remains after the fruit harvest. Instead of being discarded as agricultural waste, the pseudostem is stripped, and its outer layers are separated to extract long, silky fibers. These fibers are washed, dried, and softened before being spun into yarn. The quality of the resulting fabric depends on which part of the stem the fiber comes from: outer fibers are coarse and strong (ideal for industrial uses), while inner fibers are finer and softer (used for apparel and textiles).

Banana fabric can be woven or blended with other fibers, such as cotton, bamboo, or silk, to achieve a range of textures and finishes. The fabric has a lustrous sheen, similar to silk, but with a slightly more textured feel. It is strong, lightweight, and breathable, with excellent moisture absorption. Banana fiber is also naturally resistant to microbial growth and odor, making it well-suited for warm and humid climates. Depending on the processing technique, banana fabric can range from coarse and rustic to luxuriously soft and refined.

The sustainability profile of banana fabric is one of its greatest strengths. It is made from agricultural waste, as banana plants bear fruit only once and are typically discarded afterward. Utilizing the pseudostem reduces waste and provides additional income for farmers. The production process can be entirely natural, involving minimal chemicals and water, especially when fibers are manually extracted and processed. Banana fiber is also biodegradable and compostable, posing no environmental threat at the end of its life cycle. However, some commercial production methods use mechanical or chemical softening, which can affect the overall eco-footprint.

In fashion, banana fabric is used in apparel, scarves, and accessories, often marketed as a sustainable luxury textile. Its smooth texture and subtle luster make it a natural substitute for silk or viscose in dresses, blouses, and eveningwear. In interiors, banana fiber is woven into upholstery, curtains, and rugs, valued for its strength and natural aesthetic. The coarser grades of banana fiber are used in industrial applications, including ropes, mats, paper, and even automobile seat covers.

Banana fabric production is concentrated in India, Nepal, the Philippines, and Japan, with the regions of Assam and Tamil Nadu in India emerging as key exporters. Nepalese banana fiber weaving has also become a vital cottage industry, providing livelihoods to rural women’s cooperatives. Japan continues to preserve bashō-fu as a heritage craft, while the Philippines remains the world’s largest producer of abacá for industrial-grade applications.

Banana fabric represents the perfect balance of tradition and innovation. It transforms agricultural byproducts into beautiful, functional textiles, supporting sustainable livelihoods and reducing waste. With its natural elegance and ecological promise, banana fabric is emerging as one of the most compelling materials in the movement toward a greener fashion industry.