Cupro, short for cuprammonium rayon, is a regenerated cellulose fiber made from cotton linter, the fine, silky fibers that stick to cotton seeds after ginning. Known for its smooth, silky hand and excellent drape, cupro is often described as a vegan silk due to its luxurious feel and plant-based origin. As a byproduct of cotton production, cupro transforms what would otherwise be agricultural waste into a refined, high-quality textile, making it an innovative and sustainable alternative to both natural and synthetic fibers.

The origins of cupro date back to the late 19th century, when chemists discovered how to dissolve cellulose in a cuprammonium solution (a mixture of copper and ammonia) to produce a fine, lustrous filament. The process was patented in 1890 by Swiss chemist Matthias Eduard Schweizer and later industrialized in Japan in the early 20th century. Japan remains a leading producer of cupro today, with Asahi Kasei Corporation’s “Bemberg™” brand serving as the global standard for high-quality cupro.

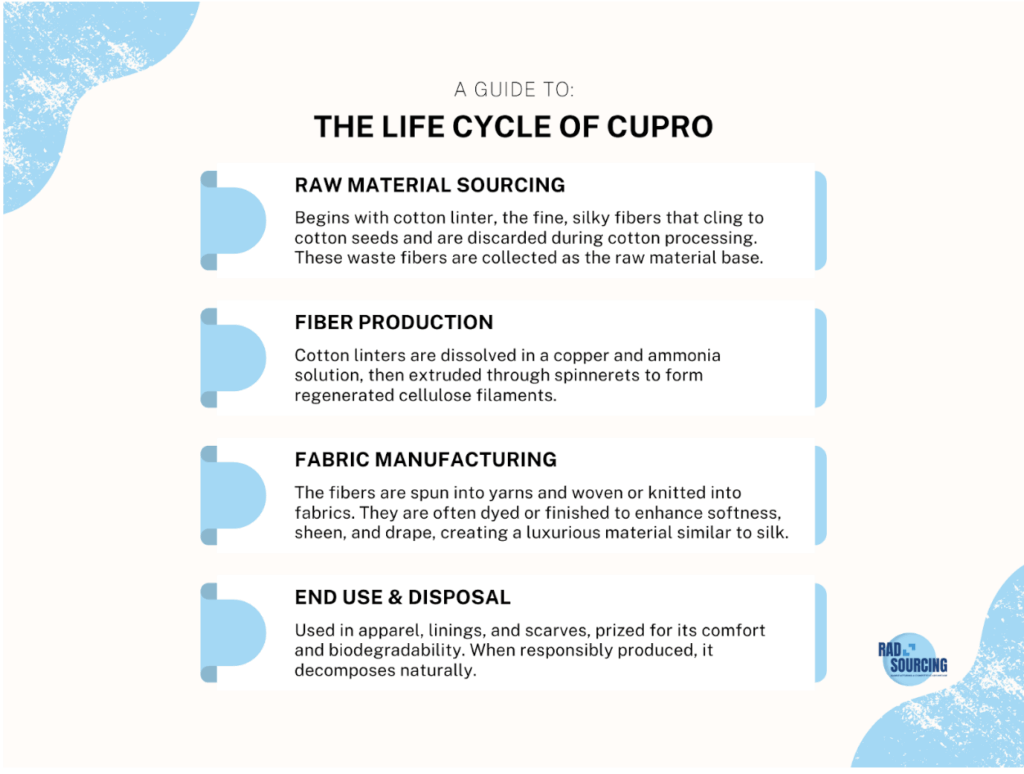

Cupro production begins with the collection of cotton linter, a waste fiber too short to spin into cotton yarn. The linter is dissolved in a copper-ammonium solution, creating a viscous liquid that is then extruded through spinnerets to form fine, continuous filaments. These filaments are washed, neutralized, and spun into fibers, resulting in a material with a silky-smooth surface, a cool touch, and fluid drape. The resulting fabric boasts a refined sheen and breathability comparable to natural silk, with enhanced moisture absorption and antistatic properties.

Cupro’s properties make it ideal for high-end apparel and linings. It is lightweight, breathable, and exceptionally soft, offering a cooling effect on the skin. Cupro has excellent dye affinity, allowing for deep, rich colors, and it resists pilling and static. Unlike many synthetics, it is also biodegradable under proper conditions. However, cupro can wrinkle easily and may require delicate handling. When used in blends, such as with viscose or polyester, it gains additional strength and wrinkle resistance while retaining its signature drape.

Cupro’s aesthetic qualities and performance have made it a popular choice in the fashion and luxury markets. It is used in dresses, blouses, linings for tailored garments, scarves, and lingerie, essentially anywhere a soft, flowing, silk-like texture is desired. It’s also increasingly seen in sustainable fashion collections, as designers seek alternatives to silk and synthetic fibers that align with eco-conscious values.

From a sustainability standpoint, cupro occupies an interesting position between natural and semi-synthetic fibers. On one hand, it is made from cotton waste, giving new life to a renewable resource and diverting agricultural byproducts from landfills. It is also biodegradable, distinguishing it from fully synthetic fibers, such as polyester. On the other hand, traditional cupro production uses a copper and ammonia-based solvent system, which can be environmentally hazardous if not properly managed. Modern manufacturers, such as Asahi Kasei, operate closed-loop systems that recover nearly all chemicals and water, making their production far safer and more sustainable. As such, responsibly made cupro ranks highly among eco-luxury materials.

Cupro is primarily produced in Japan, where Asahi Kasei’s Bemberg™ continues to dominate the global market with a reputation for exceptional quality and responsible production. Smaller quantities are also produced in China and India, though Japanese cupro remains the benchmark for sustainability and softness.

Cupro embodies the fusion of science, sustainability, and luxury. It transforms discarded plant matter into a refined, biodegradable fabric with exceptional comfort and elegance. As the fashion industry continues to pursue more ethical and sustainable materials, cupro’s unique combination of performance, softness, and ecological promise ensures its growing importance in modern textile innovation.