Elastane, commonly known by brand names such as Spandex (in the U.S.) or Lycra (a proprietary name owned by The LYCRA Company), is a synthetic fiber prized for its exceptional elasticity. Invented in 1958 by chemist Joseph Shivers at DuPont, elastane was designed to replace rubber in clothing, particularly in garments requiring flexibility and stretch. The introduction of elastane marked a significant moment in textile history, enabling the rise of form-fitting and performance-based apparel.

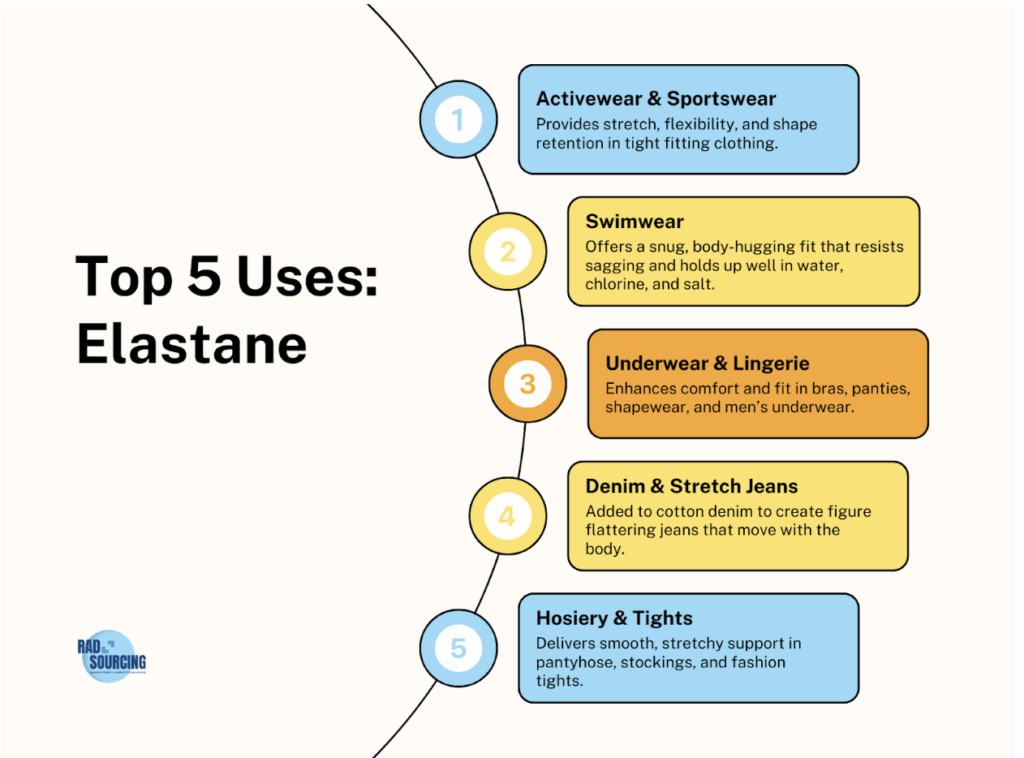

What sets elastane apart from other fibers is its ability to stretch up to five to eight times its original length and then return to its original shape without losing elasticity. This quality has made it indispensable in a wide array of garments, from athletic wear and swimwear to lingerie, shapewear, and denim. Elastane is rarely used alone; instead, it is blended in small amounts (typically 2–10%) with other fibers, such as cotton, polyester, or nylon, to impart stretch and improve comfort.

The production of elastane involves the reaction of a prepolymer, created by combining a diisocyanate compound with a macroglycol, under heat. This prepolymer is then chain-extended with a diamine. The resulting polymer is forced through spinnerets in a process known as solution-dry spinning (the most common method), creating solidified, cured filaments that are collected. The final fibers are often treated with finishing agents to improve performance and blendability.

Most elastane is produced in China, India, Brazil, and other textile manufacturing hubs in Asia. Due to its specialized production process, fewer companies produce elastane compared to other synthetic fibers, and a significant portion of the global supply is sourced from a handful of large chemical companies.

Elastane’s stretch and recovery properties give it remarkable versatility. It improves freedom of movement in activewear, creates a second-skin feel in undergarments, and enhances shape retention in fitted garments, such as skinny jeans and bodycon dresses. In technical garments, such as compression gear and medical textiles, elastane plays a vital role in providing support and comfort.

Despite its widespread use, elastane presents sustainability challenges. It is derived from petroleum and involves the use of toxic chemicals in its manufacturing, including diisocyanates and solvents. Elastane is also non-biodegradable and difficult to recycle, particularly because it is often blended with other fibers. Its presence in fabric blends can complicate the recycling of those textiles, as separating elastane from other materials is not yet an efficient or scalable process.

Another concern is the shedding of microplastics during washing, which contributes to water pollution. Although elastane may shed fewer microfibers than polyester, its synthetic nature still contributes to environmental degradation. Additionally, elastane’s durability can diminish over time with repeated wear and laundering, especially when exposed to high heat or chlorine.

Progress is being made toward developing sustainable alternatives to elastane. For example, bio-based elastane, made from renewable resources such as corn, is in development. Companies are also exploring elastane made using partially recycled content or closed-loop manufacturing methods that recover and reuse solvents. While these solutions are not yet widespread, they signal the industry’s growing commitment to circular economy principles.

Certifications like OEKO-TEX Standard 100 can help ensure that elastane used in garments has been tested for harmful substances. Additionally, consumers can prolong the life of elastane-containing garments by washing in cold water, avoiding tumble drying, and steering clear of bleach and fabric softeners.

Elastane has transformed the way clothes fit and perform. While it is a small component of many textiles, its impact on fashion, sports, and everyday comfort is enormous. As sustainability becomes more critical to both brands and consumers, elastane’s future will likely hinge on innovation in cleaner production and recycling technologies.