Gore-Tex is one of the most iconic names in performance textiles, renowned for its waterproof, windproof, and breathable protection. Developed in 1969 by Wilbert L. Gore and his son Robert W. Gore developed the technology that originated from the discovery that polytetrafluoroethylene (PTFE) could be expanded under heat and tension to form a microporous structure. This expanded PTFE (ePTFE) became the cornerstone of Gore-Tex, revolutionizing outdoor apparel and equipment by enabling fabrics that shield against rain and wind while allowing sweat vapor to escape.

The science behind Gore-Tex lies in the structure of its membrane. ePTFE contains billions of microscopic pores per square inch, each about 20,000 times smaller than a water droplet but 700 times larger than a water vapor molecule. This makes the membrane impermeable to liquid water yet permeable to vapor, striking a balance between waterproofing and breathability. To enhance durability and resistance to contamination, the ePTFE membrane is often combined with an oleophobic (oil-resistant) coating that prevents body oils and dirt from clogging its pores.

Gore-Tex fabrics are typically produced as laminates, in which the membrane is bonded to face textiles such as nylon or polyester, and sometimes to inner linings. Depending on construction, garments can be 2, 2.5, or 3-layer, with 3-layer versions providing maximum durability and protection in extreme environments. Beyond apparel, Gore-Tex membranes are used in gloves, footwear, hats, and even non-textile applications such as medical implants and industrial filters.

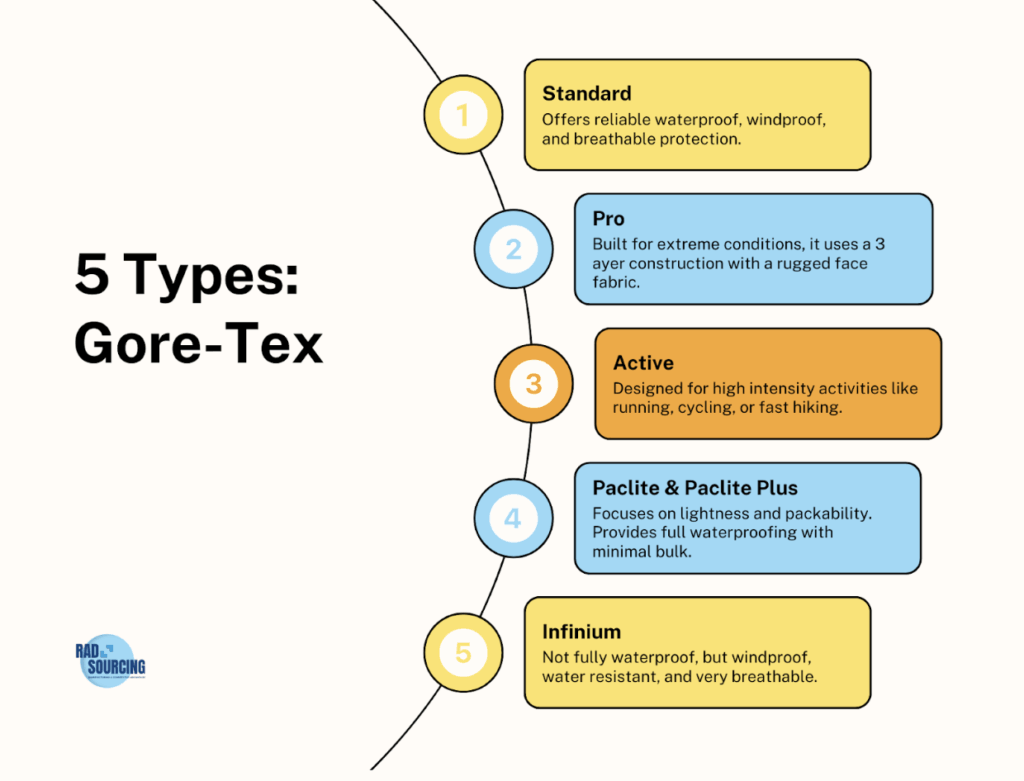

Key properties of Gore-Tex include reliable waterproofing, windproofing, and breathability. It has become a gold standard for outdoor enthusiasts, athletes, and military personnel who need protection in harsh environments. Hiking jackets, ski gear, mountaineering apparel, and tactical uniforms often feature Gore-Tex for its dependable performance. The brand has also developed specialized lines, including Gore-Tex Pro (for extreme durability), Gore-Tex Active (for high-intensity activities), and Gore-Tex Infinium (for comfort and windproofing without waterproofing).

From a sustainability perspective, Gore-Tex has faced challenges. The membrane itself is made from fluoropolymers derived from petrochemicals and is non-biodegradable. For decades, the water- and oil-repellent finishes applied to Gore-Tex products contained perfluorinated compounds (PFCs), which are persistent in the environment. In recent years, Gore has committed to eliminating harmful PFCs of environmental concern (PFCec) from its consumer products, transitioning to more eco-friendly alternatives. Additionally, Gore-Tex garments are highly durable, extending product lifespans and reducing waste, a positive factor for sustainability.

Global production of Gore-Tex is tightly controlled by W. L. Gore & Associates, which licenses the technology only to approved manufacturers. This ensures consistent quality but also means Gore-Tex remains a premium material. Its presence spans top outdoor brands, such as The North Face, Arc’teryx, and Patagonia, as well as specialized manufacturers of military and safety gear.

Culturally, Gore-Tex has transcended its technical roots to become a fashion statement. It is featured not only in mountaineering gear but also in urban streetwear collaborations with brands like Supreme and Nike, symbolizing both performance and style.

Gore-Tex represents the intersection of science, performance, and branding in modern textiles. Its groundbreaking membrane technology set a standard for waterproof fabrics, and while environmental concerns persist, the brand’s ongoing innovation and global recognition ensure its continued prominence in both technical and fashion markets.