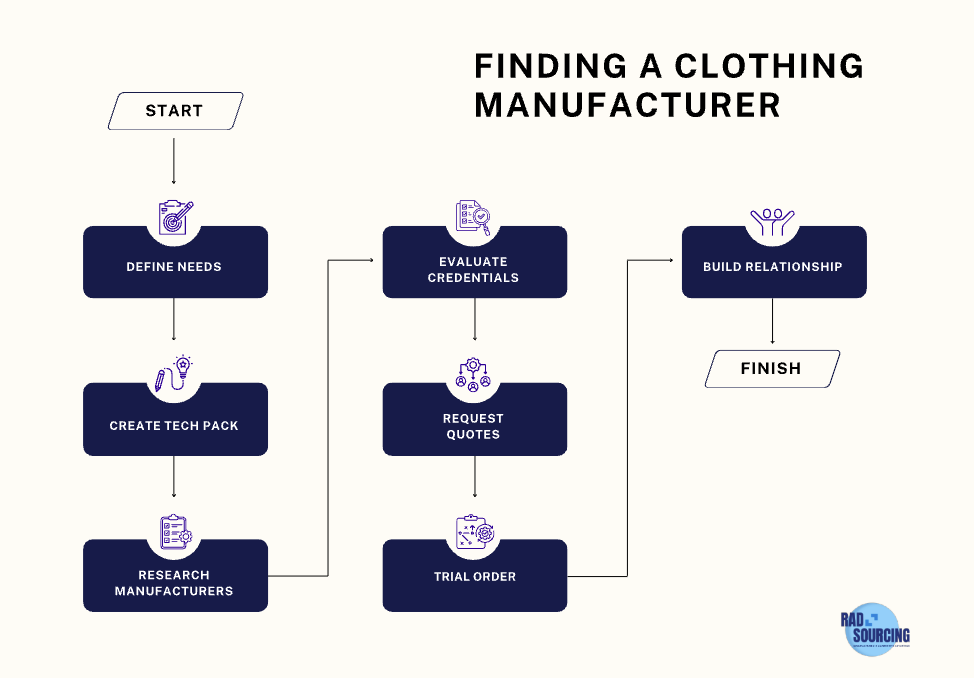

Launching or scaling a fashion brand is an exciting journey, but finding the right clothing manufacturer can make or break your success. Over the years, I’ve learned that the right partner isn’t just about cost—it’s about quality, reliability, and alignment with your brand’s vision. Here’s my step-by-step guide to help you find a manufacturer that’s the perfect fit for your brand.

1. Define Your Manufacturing Needs

Before diving into the search, take a moment to reflect on what your brand truly needs. Ask yourself:

- What type of clothing am I producing? (e.g., casual wear, activewear, luxury pieces)

- What’s my production volume? (small-batch vs. large-scale)

- Are there specific materials or sustainability standards I want to prioritize?

- Do I need custom branding like private labels or embroidery?

I’ve found that being crystal clear about these details upfront saves time and ensures you’re targeting manufacturers who can meet your expectations. For example, when we worked with a client launching an eco-friendly activewear line, we prioritized manufacturers with GOTS certifications and experience in performance fabrics.

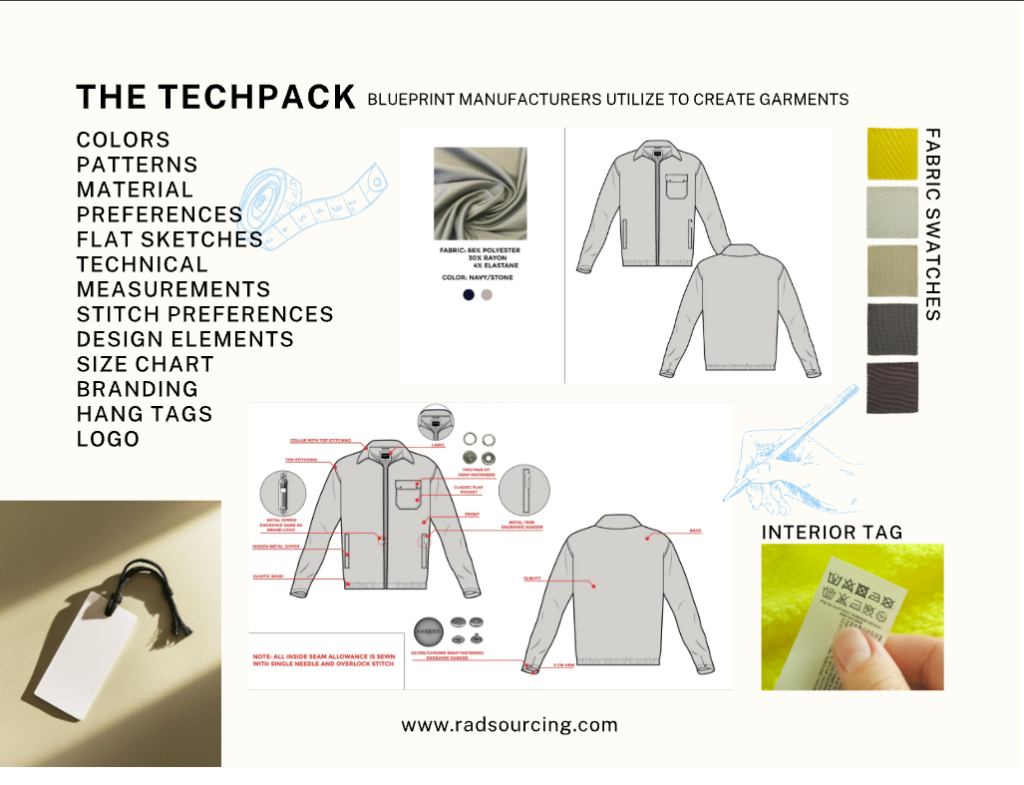

2. Create a Detailed Tech Pack

A tech pack is your blueprint for success. It’s not just a document—it’s your way of communicating your vision to the manufacturer. I always recommend including:

- Detailed sketches or CAD drawings

- Fabric and trim specifications

- Sizing and measurement charts

- Construction and finishing details

- Packaging and labeling requirements

When new brands skip this step it can lead to costly misunderstandings during production. Trust me, a well-prepared tech pack is worth the effort. I highly suggest working with a professional designer like the ones we have in house at Rad Sourcing.

3. Research Potential Manufacturers

Finding the right manufacturer takes time and effort. Here’s how I would approach it:

- Online Directories: Platforms like Maker’s Row, Alibaba, and Kompass are great starting points.

- Trade Shows: Attending events like MAGIC or Première Vision can help you connect with manufacturers face-to-face and build trust.

- Referrals: Don’t underestimate the power of networking. Ask fellow designers or join fashion forums like the ones on Reddit for recommendations.

- Sourcing Agents: If you’re overwhelmed, partnering with a sourcing agent like Rad Sourcing can streamline the process.

One of my favorite success stories involves a client who struggled to find a manufacturer for their intricate knitwear designs. Through a referral at a trade show, we found a small family-owned factory in Italy that specialized in high-end knits. The result? Stunning quality and a long-term partnership.

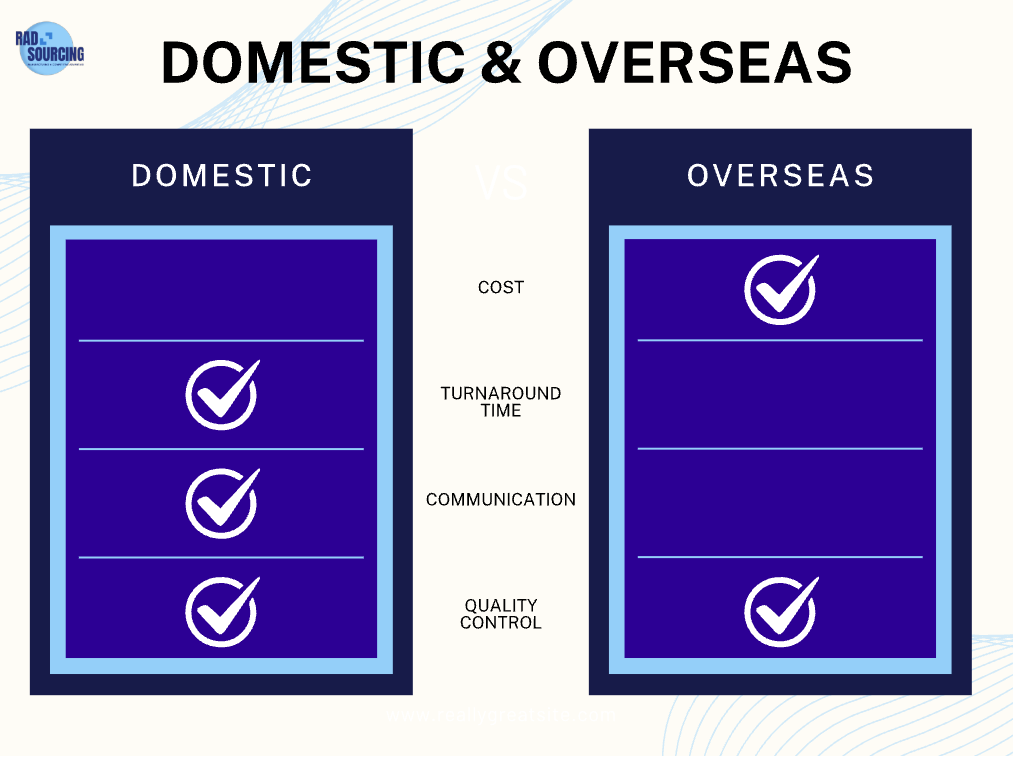

4. Domestic vs. Overseas Manufacturing

This is a big decision, and it depends on your priorities. Here’s my take:

- Domestic Manufacturers: Ideal for faster turnaround times, easier communication, and stricter quality control. However, they’re often much more expensive.

- Overseas Manufacturers: Great for cost savings, but you’ll need to factor in longer lead times and potential quality control challenges.

I’ve worked with both, and each has its pros and cons. For example, when I helped a startup produce their first collection, we opted for a domestic manufacturer to ensure quick revisions and high-quality samples. For larger orders, we transitioned to an overseas partner to reduce costs.

5. Evaluate Manufacturer Credentials

Not all manufacturers are created equal. Here’s how we vet potential partners:

- Certifications: Look for ISO, WRAP, or GOTS certifications, especially if sustainability is a priority.

- Samples: Always request samples to assess quality firsthand.

- Client Testimonials: Reach out to past clients to hear about their experiences.

- MOQs and Pricing: Be upfront about your budget and production needs.

We have worked with manufacturers who had glowing reviews but failed to deliver on quality. That is why are overseas team members always insist on visiting the factory to see their operation in person.

6. Request Quotes and Negotiate Terms

Once you’ve narrowed down your options, request detailed quotes. Pay attention to:

- Cost per unit

- Turnaround time

- Payment terms

- Shipping and logistics

Don’t be afraid to negotiate. I’ve found that many manufacturers are willing to adjust terms, especially if you’re planning a long-term partnership.

7. Place a Trial Order

Before committing to a large order, start with a small trial run. This allows you to test the manufacturer’s quality, communication, and reliability. I’ve seen brands skip this step and end up with thousands of defective units. A trial order is your safety net.

8. Build a Strong Relationship

Your manufacturer is more than a vendor—they’re a partner in your brand’s success. Maintain open communication, provide constructive feedback, and treat them as an extension of your team. Our team has been working with some of the same manufacturers for over seven years, and their partnership has only grown stronger with time.

Final Thoughts

Finding the right clothing manufacturer is a journey, but it’s one of the most rewarding steps in building your brand. If you’re feeling overwhelmed, remember that you don’t have to do it alone. At Rad Sourcing, we’ve helped countless brands navigate this process, from creating tech packs to connecting them with trusted manufacturers.

Ready to take the next step? Let’s bring your designs to life. Contact us today at www.radsourcing.com to get started!