Jute is a long, soft, and shiny plant-based fiber known for its strength, breathability, and eco-friendly qualities. Often referred to as the “golden fiber” for its natural golden sheen and economic importance, jute is one of the most widely used natural fibers in the world, second only to cotton. Durable, biodegradable, and inexpensive, jute plays a vital role in both traditional handicrafts and modern sustainable design, bridging the realms of agriculture, industry, and fashion.

The cultivation and use of jute date back thousands of years, primarily in the Ganges Delta region, which spans India and Bangladesh, where the warm, humid climate and fertile soil create ideal growing conditions. Historical records suggest that jute was used as early as the 3rd millennium BCE for ropes and textiles in the Indus Valley Civilization. By the 19th century, jute had become a major global commodity, driving the growth of the Bengal jute industry under British colonial rule. Factories in Kolkata (then Calcutta) and Dundee, Scotland, turned raw jute into sacks, ropes, and packaging materials that powered global trade.

Jute is obtained from the bast (inner bark) of the jute plant, primarily from two species: Corchorus capsularis (white jute) and Corchorus olitorius (tossa jute). The production process begins with harvesting the stalks at maturity, followed by retting, where the stems are soaked in water to loosen the fibers from the woody core. After retting, the fibers are stripped, washed, and dried before being spun into coarse, strong yarns. This labor-intensive, largely manual process has mainly remained traditional in jute-producing regions, providing livelihoods to millions of rural farmers and workers.

Jute’s properties make it highly versatile and sustainable. It is strong, breathable, and naturally resistant to static and UV rays. The fibers have a rough texture but can be softened through processing or blending with other materials. Jute’s moisture-absorbent and insulating qualities make it ideal for both warm and cool environments. Unlike synthetic fibers, jute is biodegradable and compostable, breaking down naturally without releasing harmful substances. Its rapid growth cycle, maturing in just 4–6 months, makes it a highly renewable resource that requires minimal fertilizer and pesticide use.

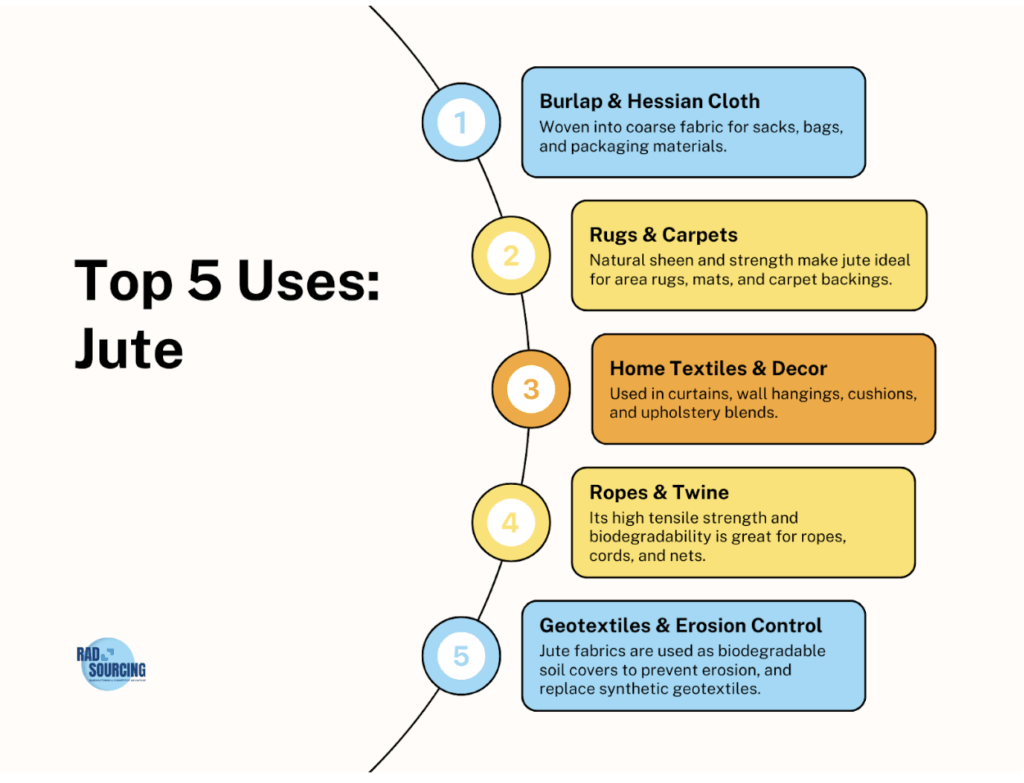

Jute’s traditional uses center on packaging and utility. It is the primary material for gunny sacks, ropes, mats, rugs, and twine, as well as agricultural and industrial textiles, such as burlap (also known as hessian). In home décor, jute has gained popularity in rugs, baskets, and wall hangings, appreciated for its rustic, earthy aesthetic. In the fashion industry, designers are increasingly incorporating blended jute fabrics into their bags, shoes, and accessories as part of their sustainable collections. When mixed with cotton, silk, or synthetic fibers, jute gains softness and flexibility, expanding its range of applications.

In recent years, jute has also become a key player in eco-friendly innovation. It is being developed into nonwoven fabrics, composite materials, and bioplastics, offering alternatives to petroleum-based products. Jute fiber composites are now utilized in automobile interiors, construction panels, and eco-packaging, leveraging the material’s strength and biodegradability. These innovations have positioned jute as a cornerstone of the circular economy, turning agricultural output into renewable, recyclable industrial materials.

From a sustainability standpoint, jute is one of the most environmentally responsible fibers available. The plant absorbs large amounts of carbon dioxide and releases oxygen at a rate higher than most crops, helping improve air quality and soil fertility. It requires little water and grows without the intensive chemical inputs associated with cotton. Moreover, the residual woody core (known as jute stick) serves as fuel or raw material for particle boards and pulp, ensuring minimal waste. The primary environmental challenge lies in retting, which can pollute waterways if not properly managed; however, efforts are underway to develop cleaner retting technologies.

Today, the leading producers of jute are Bangladesh, India, and China, with Bangladesh recognized for producing the finest quality fibers. The Bangladesh Jute Research Institute (BJRI) and various global organizations continue to modernize jute cultivation, processing, and product diversification. India remains a major exporter of jute products, particularly yarn and fabric, while Bangladesh leads in raw fiber production and innovation in jute composites.

Jute’s enduring appeal lies in its perfect balance of function, beauty, and sustainability. Once valued mainly for utility, it now stands as a symbol of ecological innovation and craftsmanship. As the world moves toward greener materials and reduced reliance on plastic, jute continues to prove that ancient fibers can power the future of sustainable design.