Milk fabric, also known as casein fiber or milk silk, is an innovative bio-based textile made from the protein found in milk. Combining the luxury of silk with the comfort of natural fibers, milk fabric is smooth, breathable, and biodegradable. Initially developed in the early 20th century as a sustainable alternative to wool and silk, this fabric has recently re-emerged as part of the growing movement toward bio-fabrics and circular textiles, utilizing waste milk that would otherwise be discarded.

The origins of milk fabric date back to the 1930s, when Italian chemist Antonio Ferretti patented a process for transforming milk casein, a byproduct of milk, into textile fiber. During this period, Europe faced material shortages due to war and economic instability, prompting the search for alternative fibers. Italy produced the first commercial casein-based fiber, Lanital, while Germany manufactured a similar version, Aralac. These early fibers resembled wool in softness but were difficult to produce in large quantities and prone to weakening when wet. After World War II, milk fiber production declined as inexpensive synthetics such as nylon and polyester became available. However, advances in green chemistry have since revived interest in milk fabric as a sustainable, protein-based fiber suited for modern, eco-conscious design.

The production process for milk fabric begins with dehydrated, skimmed milk, often sourced from dairy waste unsuitable for human consumption. The milk is fermented to extract casein, a natural protein that serves as the main raw material. The casein is then dissolved in an alkaline solution, filtered, and extruded through spinnerets to form fine filaments, which are then hardened in a chemical bath. These fibers are washed, dried, and spun into yarn. Modern production methods, particularly those developed in China and Germany, employ non-toxic, closed-loop systems that recover and recycle the water and chemicals used in the process, thereby dramatically reducing environmental impact.

The properties of milk fabric are what make it unique among natural and bio-based fibers. It has a silky, soft texture with a smooth hand feel comparable to cashmere or silk. The fabric is lightweight, breathable, and moisture-absorbent, making it ideal for sensitive skin. Because casein is a natural protein, milk fabric is hypoallergenic and antibacterial, resisting odor and bacterial growth without the need for chemical finishes. It also features excellent drape and colorfastness, evenly holding dyes and maintaining its shape well over time. Unlike synthetic fabrics, milk fabric is biodegradable, breaking down naturally without leaving harmful residues.

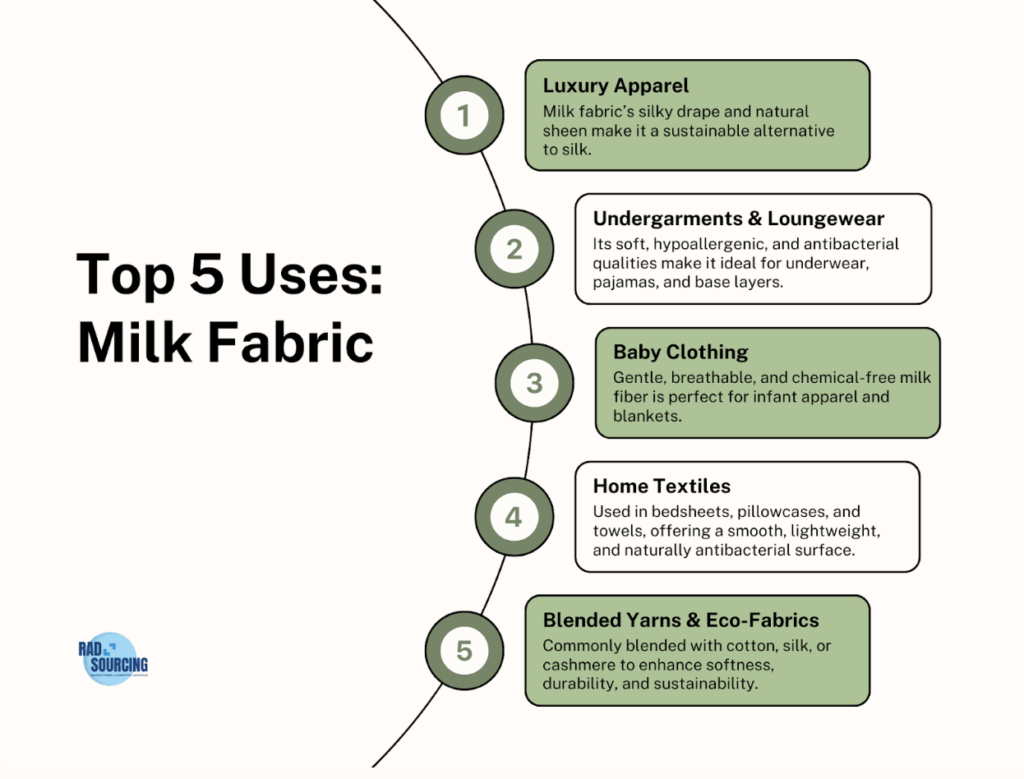

In fashion and textiles, milk fabric is used for luxury apparel, lingerie, baby clothing, sleepwear, and eco-loungewear, where softness and skin compatibility are priorities. It is often blended with other natural fibers such as cotton, silk, or cashmere to enhance comfort and durability. In the home textile industry, it is used for bedding, pillowcases, and towels, offering a naturally smooth surface with antibacterial benefits. Its light sheen and fluid drape also make it suitable for high-end dresses and knitwear, especially in collections emphasizing sustainable or innovative materials.

From a sustainability perspective, milk fabric presents an intriguing model for circular resource use. It repurposes waste milk, often discarded by the dairy industry due to spoilage or overproduction, into a renewable raw material. According to some manufacturers, one kilogram of milk fiber can be produced using approximately two liters of waste milk, thereby transforming potential food waste into a valuable textile. Moreover, when made through modern, formaldehyde-free processes, milk fabric is biodegradable, non-toxic, and compostable. However, its sustainability depends heavily on the production method: early forms of casein fiber required strong chemicals, such as formaldehyde, to stabilize the protein, while newer processes (like those used by the German company Qmilch) rely on heat and natural cross-linking instead, achieving a completely eco-friendly process.

One limitation of milk fabric is its cost and scalability. The production process is complex and more expensive than cotton or synthetic alternatives, making milk fabric a niche product rather than a mass-market material. Nonetheless, it holds promise for luxury and specialty markets, where innovation, comfort, and sustainability justify higher production costs.

Globally, the modern revival of milk fabric is being driven by Germany and China, with companies like Qmilch GmbH pioneering the use of renewable casein fiber made entirely from non-food milk waste. Small-scale producers in Italy, Japan, and India have also experimented with milk-based blends as part of eco-textile innovation projects. As consumers increasingly demand materials that reduce waste and environmental harm, milk fabric’s closed-loop potential has positioned it as one of the most forward-looking fibers in sustainable fashion.

Milk fabric represents a remarkable intersection of biotechnology and textile design, a material that transforms waste into a luxury product. Its silky softness, natural antibacterial properties, and sustainable production make it a symbol of innovation in the search for responsible alternatives to petroleum-based fibers. As the fashion industry continues to explore circular materials, milk fabric stands as proof that even a humble byproduct can become a fabric of the future, combining comfort, conscience, and creativity.