Modal is a semi-synthetic cellulose fiber celebrated for its exceptional softness, smooth drape, and moisture-absorbing qualities. Known as one of the most luxurious forms of rayon, Modal combines the comfort of natural fibers with the performance of modern textile engineering. Made primarily from beechwood pulp, it offers a silky touch similar to that of cotton and silk, but with enhanced durability and environmental efficiency, especially when produced using closed-loop manufacturing systems.

The history of Modal dates back to the 1950s, when it was first developed in Japan as a more advanced version of viscose rayon. While viscose had been popular since the early 20th century for its silk-like qualities, it was prone to shrinkage and loss of strength when wet. Modal improved upon these drawbacks by refining processing and polymer structure, resulting in a stronger, more stable fiber. By the 1960s, the Austrian company Lenzing AG commercialized Modal under its now-famous Lenzing Modal brand, setting a global standard for sustainable and high-quality cellulose-based textiles.

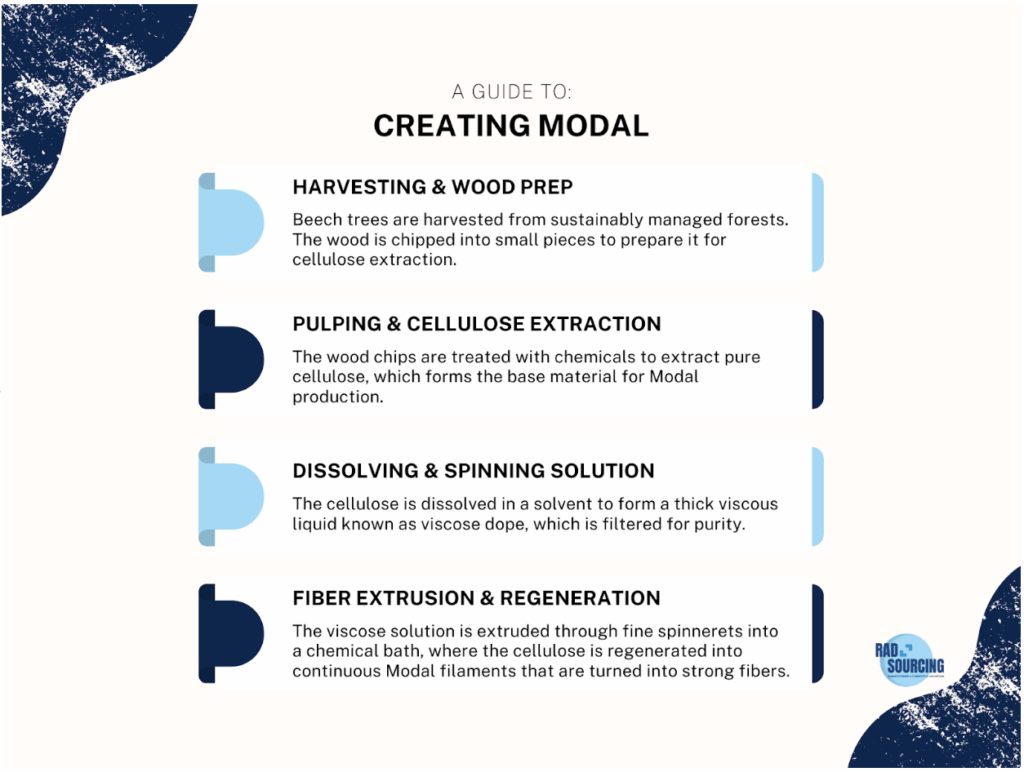

Modal is made from beechwood cellulose, primarily sourced from sustainably managed forests in Europe. The manufacturing process begins by chipping the wood and converting it into pulp, which is then dissolved in a sodium hydroxide solution to extract pure cellulose. This cellulose is converted to a viscous liquid by reacting with carbon disulfide, then extruded through fine spinnerets to form continuous fibers. Unlike traditional viscose production, Lenzing’s closed-loop system recovers and reuses about 95% of solvents and water, minimizing environmental pollution and waste.

The properties of Modal make it one of the most comfortable and versatile fabrics available. It is exceptionally soft, smooth against the skin, and highly breathable. Modal fibers are finer and stronger than standard viscose, imparting the fabric with a natural sheen and a silky drape. The material is also more durable, maintaining its shape and strength even when wet. It absorbs 50% more moisture than cotton, making it ideal for activewear, underwear, and sleepwear. Modal is also resistant to shrinkage and pilling, offering long-lasting comfort and easy maintenance.

In fashion and textiles, Modal is used in a variety of products that require softness and flexibility. Common applications include T-shirts, dresses, lingerie, loungewear, activewear, and bedding. Because it blends easily with other fibers, such as cotton, elastane, or polyester, it enhances the fabric’s hand feel while maintaining strength and stretch. Modal-cotton blends are especially popular, combining cotton’s breathability with Modal’s silkiness and moisture control. Luxury brands and eco-conscious designers often choose Modal for its elevated tactile experience and sustainable appeal.

From a sustainability standpoint, Modal falls between natural and synthetic fibers. It is derived from renewable wood sources, and when produced under responsible conditions, such as those in Lenzing’s certified supply chain, it is biodegradable and carbon-neutral. Compared to cotton, Modal requires significantly less water and land, as beech trees are naturally regenerative and do not rely heavily on irrigation or pesticides. The use of closed-loop production methods further reduces the environmental footprint by recycling water and chemicals, thereby minimizing waste. However, not all Modal on the market is produced under such conditions; uncertified producers may still use traditional viscose methods that release harmful effluents. Therefore, sourcing TENCEL Modal or Lenzing Modal ensures adherence to high sustainability standards.

The textile industry often distinguishes between different types of Modal based on processing and fineness.

- Standard Modal: known for softness, used widely in apparel and linings.

- MicroModal®: a finer version with even smoother texture and drape, ideal for premium underwear and luxury basics.

- Modal Blends: often combined with spandex, cotton, or lyocell to improve stretch and durability.

Globally, Austria (Lenzing) remains the leader in sustainable Modal production, with additional manufacturing in China, India, and Indonesia, where demand for affordable semi-synthetic fibers continues to grow. European producers dominate the high-end market, supplying the fashion and home textile industries, which are focused on traceability and eco-certification.

Modal represents the perfect union of comfort, performance, and sustainability. Its silky hand, moisture management, and environmental advantages make it a standout among modern fibers. As consumer demand grows for eco-luxury materials that feel as good as they perform, Modal continues to define the standard for sustainable softness, proof that innovation in textiles can create beauty that’s both tactile and responsible.