OutDry is a waterproof and breathable fabric technology developed in Italy in the early 2000s by Nextec S.r.l., which Columbia Sportswear later acquired. It was designed to address the limitations of traditional waterproof-breathable systems, particularly in gloves, footwear, and outdoor gear, where bulk and water absorption can compromise performance. OutDry’s defining innovation is its direct lamination process, which bonds a waterproof membrane directly to the inside of the outer fabric, eliminating the air gap that typically exists in other constructions.

The structure of OutDry is based on a microporous membrane, usually made from polyurethane (PU), that contains microscopic pores small enough to block liquid water while remaining permeable to water vapor. Unlike other waterproof technologies, such as Gore-Tex or eVent, that insert the membrane as a separate layer within a fabric sandwich, OutDry laminates the membrane directly to the inner side of the face fabric. This prevents water from seeping into the outer fabric, where it would otherwise increase weight, reduce insulation, and compromise breathability.

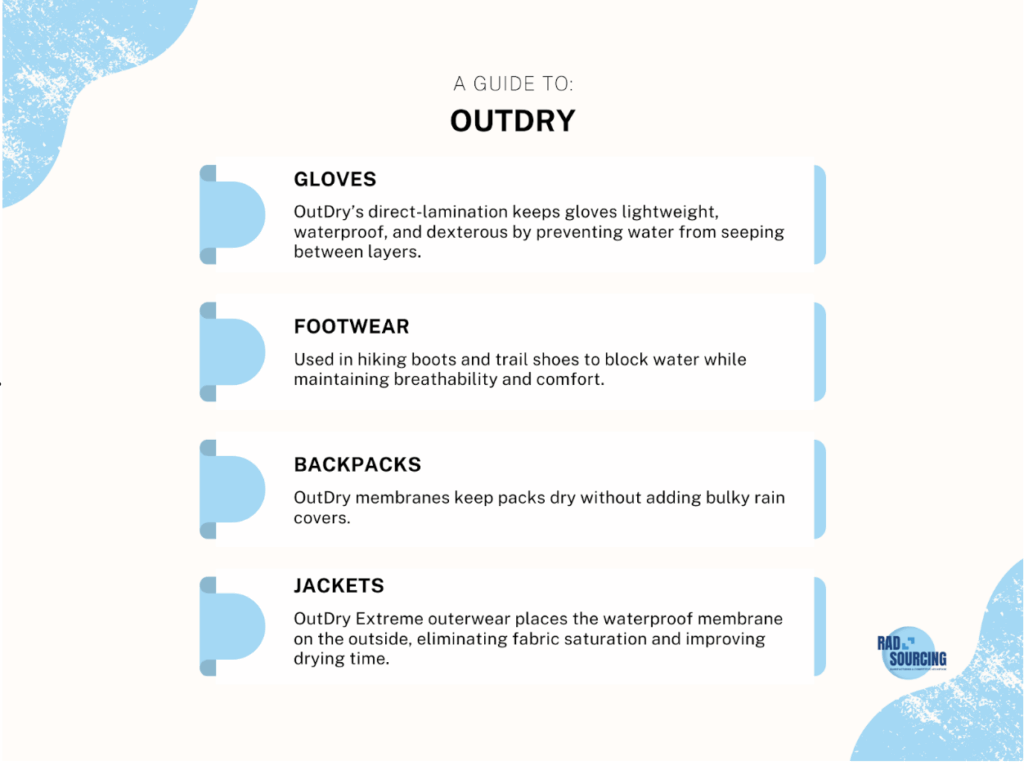

This construction gives OutDry several key advantages. First, it eliminates the “wet-out” effect, where the outer layer of fabric becomes saturated with water, causing discomfort and reducing performance. Second, it allows for a more precise and seamless fit in gloves and shoes, where multiple layers can reduce dexterity and comfort. Third, OutDry products are typically lighter and less bulky while maintaining waterproofness and breathability.

The properties of OutDry include reliable waterproofing (often rated to withstand hydrostatic pressures suitable for extreme conditions), excellent wind resistance, and good moisture management. Because the membrane is directly bonded, the outer fabric dries faster and resists waterlogging, making it particularly useful in wet and snowy environments. OutDry is also highly durable, with membranes designed to maintain performance over time, even with repeated use.

From a sustainability perspective, OutDry faces many of the same challenges as synthetic waterproof technologies. The PU membrane and synthetic face fabrics are derived from petrochemicals and are not biodegradable. Additionally, durable water repellent (DWR) treatments applied to the outer surface have historically contained perfluorinated compounds (PFCs), which are persistent in the environment. Columbia Sportswear has been transitioning its OutDry products toward PFC-free DWR finishes to reduce environmental harm. While durability extends the lifespan of OutDry gear, end-of-life recyclability remains limited due to the laminated construction.

OutDry is used primarily in gloves, footwear, backpacks, and outerwear designed for outdoor sports, mountaineering, and everyday wet-weather protection. Columbia integrates OutDry into a wide range of its products, branding it as OutDry Extreme in outerwear lines to highlight its external membrane construction. Unlike many competitors, OutDry jackets often feature the waterproof membrane on the outside of the garment, eliminating the need for a face fabric that can saturate with water.

OutDry represents a clever rethinking of waterproof-breathable technology. By addressing the weaknesses of multilayer constructions, it delivers lighter, drier, and more comfortable gear for outdoor enthusiasts. While sustainability challenges remain, its functional innovations ensure OutDry remains a respected option in the performance apparel and equipment market.