Polyamide is the technical term for a family of synthetic fibers made from repeating units linked by amide bonds. The most well-known polyamide is nylon, first synthesized in 1935 by Wallace Carothers at DuPont. While the term “nylon” is often used generically, polyamide refers more broadly to a category that includes variations like Nylon 6, Nylon 6,6, and other engineering-grade polyamides used in both textiles and industrial applications.

The invention of polyamide fibers marked the dawn of the synthetic textile era. Nylon 6,6, the first commercial polyamide fiber, was introduced to the public in the late 1930s and was famously used in women’s stockings that offered a silk-like sheen and greater durability. During World War II, polyamide fibers were diverted to make parachutes, ropes, and other military materials. After the war, their use in civilian clothing and industrial fabrics skyrocketed.

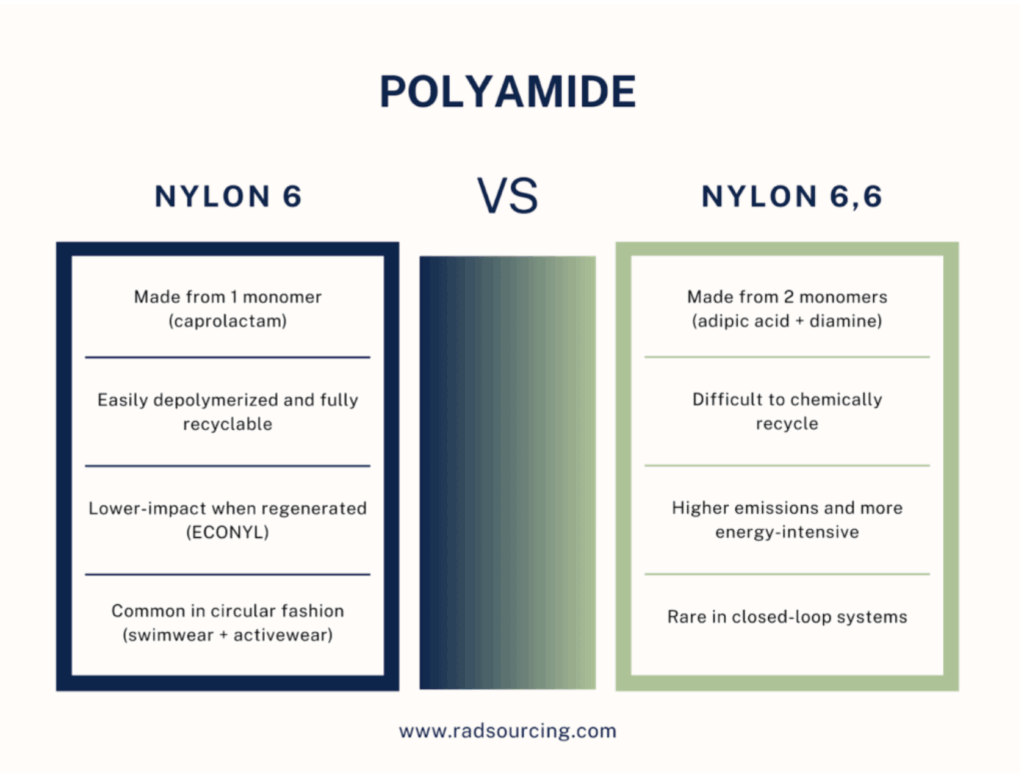

Polyamide is produced by a chemical process called polycondensation. In the case of Nylon 6,6, two monomers, adipic acid and hexamethylenediamine, are combined to form a salt, which is then polymerized at high temperatures. For Nylon 6, a ring-shaped monomer called caprolactam is used. The resulting polymer is melted and extruded through spinnerets to form continuous filaments. These filaments are then cooled, stretched, and texturized to create fibers that can be woven or knit into fabric.

The properties of polyamide fibers make them extremely versatile. They are strong, elastic, and abrasion-resistant, with excellent resilience and recovery after stretching. Polyamides are also lightweight, quick-drying, and resistant to mildew and chemicals. These attributes make them ideal for applications in sportswear, swimwear, hosiery, lingerie, outerwear, and carpeting. Polyamide fabrics can be engineered for a wide range of textures, from smooth and silky to structured and durable.

In addition to apparel, polyamide is used in various industrial products, including fishing lines, tire cords, upholstery, and technical textiles. Its adaptability has made it one of the most widely used synthetic fibers globally.

From a sustainability perspective, polyamide has some significant drawbacks. It is derived from petrochemicals and is energy-intensive to produce. The production of Nylon 6,6, in particular, emits nitrous oxide, a greenhouse gas with a much higher warming potential than CO2. Polyamide fibers are not biodegradable and contribute to microplastic pollution during laundering.

However, innovations in recycling and bio-based alternatives are helping to mitigate the environmental impact of polyamides. Recycled polyamide, often made from pre- and post-consumer waste such as fishing nets, carpets, and fabric scraps, is gaining momentum. ECONYL® is one of the leading brands in this area, producing regenerated Nylon 6 that can be recycled indefinitely without loss of quality. Bio-based polyamides made from castor oil or other renewable sources are also in development.

When evaluating sustainability, it’s important to distinguish between virgin and recycled polyamides and to consider the specific polyamide type. Certifications such as OEKO-TEX, Bluesign®, and GRS (Global Recycled Standard) help consumers and designers identify responsibly produced fibers.

Polyamide is a cornerstone of modern textiles, offering high performance and flexibility in countless applications. As the fashion and textile industries confront environmental challenges, the evolution of polyamide will hinge on advances in recycling technology, greener production methods, and circular design thinking.