Polyester is one of the most widely used synthetic fibers worldwide, valued for its strength, durability, wrinkle resistance, and versatility. Made from petroleum-derived polymers, polyester has revolutionized the textile industry since its commercial introduction in the mid-20th century. From fashion and home furnishings to technical and industrial applications, polyester’s adaptability and low cost have made it a cornerstone of modern fabric production. Today, it is both a symbol of convenience and a focal point in discussions about sustainability and circular innovation.

The origins of polyester date back to the 1930s, when British chemists John Rex Whinfield and James Tennant Dickson of Imperial Chemical Industries (ICI) first developed polyethylene terephthalate (PET), the same polymer used today in both textiles and plastic bottles. The invention was later commercialized by DuPont under the brand name Dacron® in the 1950s, marking the beginning of polyester’s rapid expansion in global markets. Affordable, easy to care for, and resistant to shrinking and stretching, polyester soon became a dominant material in clothing, especially during the 1970s.

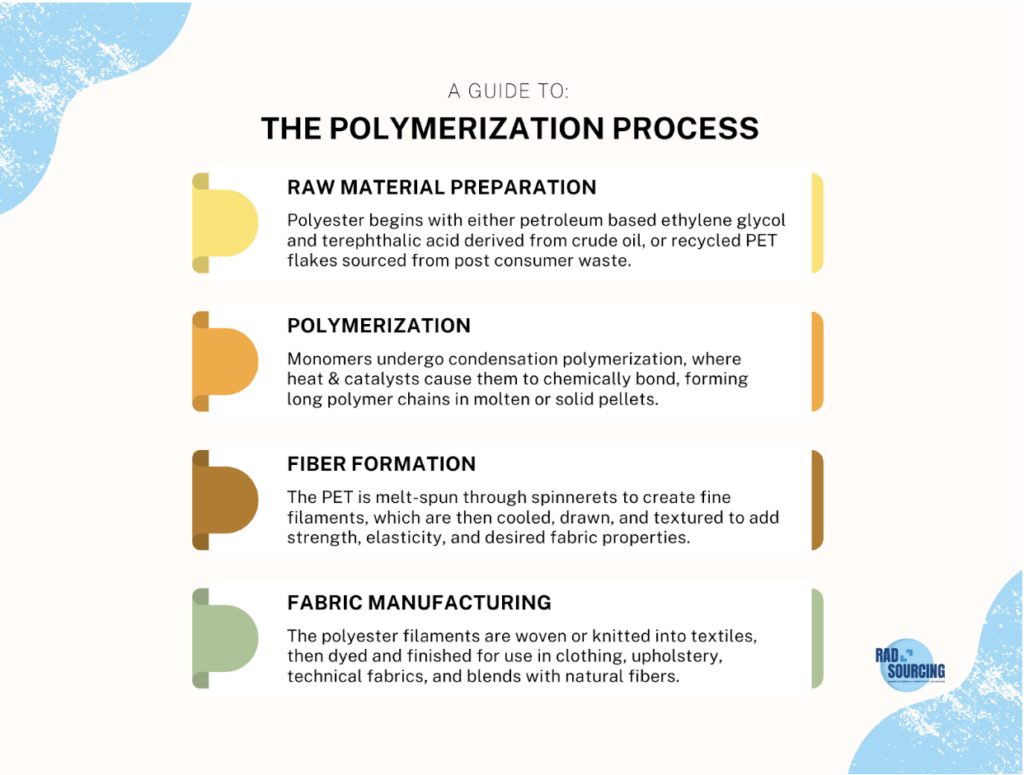

Polyester is produced through a chemical process called polymerization, in which purified terephthalic acid (PTA) reacts with ethylene glycol (EG), both derived from crude oil. This reaction forms long-chain polymers that are melted, extruded through spinnerets, and cooled into continuous filaments. These filaments can be cut into staple fibers (to mimic cotton), textured for elasticity, or left continuous for use in smooth, shiny fabrics. The resulting fiber is strong, lightweight, and highly versatile, capable of mimicking everything from silk to wool, depending on the finish and weave.

The properties of polyester have made it a powerhouse of the textile industry. It is strong, abrasion-resistant, and quick-drying, with excellent shape retention and wrinkle resistance. Polyester fibers are also hydrophobic, meaning they repel moisture, which helps garments dry quickly; however, this can make them less breathable than natural fibers. The fabric holds color well, resists fading, and blends easily with other fibers, such as cotton, wool, or spandex, to enhance comfort and performance. These traits make polyester ideal for applications ranging from sportswear and outdoor gear to home textiles, upholstery, and industrial fabrics.

Polyester’s versatility extends across multiple industries. In fashion, it is used for dresses, shirts, linings, jackets, and activewear. In home décor, it is often featured in curtains, bedding, and carpets due to its durability and resistance to stains. Technical polyester fabrics, such as microfiber and ripstop, are used in a range of applications, including tents, airbags, conveyor belts, and ropes. The fiber’s adaptability allows it to be woven, knitted, brushed, or coated, creating textures that range from sleek satin to cozy fleece.

However, polyester’s dominance comes with environmental challenges. As a synthetic polymer made from petrochemicals, it relies heavily on fossil fuels and contributes to greenhouse gas emissions during production. Polyester fabrics also shed microplastic fibers during washing, which can pollute waterways and enter marine ecosystems. Moreover, conventional polyester is non-biodegradable, persisting for decades in landfills. These concerns have sparked significant innovation in recent years, leading to more sustainable production and circular design.

The most significant development has been the use of recycled polyester (rPET), which is made by converting post-consumer plastic bottles and industrial waste into new fibers. rPET production uses less energy and water and emits fewer carbon emissions than virgin polyester, while reducing plastic waste. Many global brands, including Patagonia, Adidas, H&M, and The North Face, have incorporated recycled polyester into their collections. Beyond recycling, companies are exploring bio-based polyesters made from renewable resources, such as corn sugar, and chemical recycling technologies that can depolymerize polyester back into raw monomers for infinite reuse.

Despite these advances, recycled polyester still faces limitations. Mechanical recycling can degrade fiber quality over time, and while it reduces waste, it does not eliminate microplastic shedding. As a result, the next frontier for polyester sustainability lies in closed-loop systems, improved filtration technologies, and consumer education about garment care and longevity.

Global polyester production is led by China, which accounts for more than two-thirds of total output, followed by India, Taiwan, South Korea, and the United States. Polyester’s ubiquity across global supply chains has made it indispensable to both the fast fashion and technical industries, and it is also a key area for reform in the movement toward responsible manufacturing.

Polyester’s story is one of innovation and reinvention. Initially praised for its convenience and affordability, it now sits at the center of efforts to reconcile performance with environmental responsibility. As the textile industry continues to evolve, polyester remains both a challenge and an opportunity, demonstrating that the future of fashion depends not just on new materials but on rethinking how we produce, utilize, and recycle them.