Polypropylene, often abbreviated as PP, is a thermoplastic fiber that has revolutionized modern textiles with its affordability, durability, and lightweight feel. First polymerized in 1951 by Paul Hogan and Robert Banks, the material gained commercial significance when Italian chemist Giulio Natta developed the Ziegler-Natta catalyst, which enabled the controlled production of isotactic polypropylene. By 1957, large-scale manufacturing had begun in Europe, and the fiber quickly found widespread use not only in packaging and industrial applications but also in clothing and household textiles.

As a textile fiber, polypropylene stands out for its unique properties. It is inherently hydrophobic, meaning it does not absorb water. This makes it exceptionally good at wicking moisture away from the skin, a property highly valued in sportswear and base layers. Polypropylene is also extremely lightweight—lighter than water, in fact—which contributes to its comfort in everyday use. Despite its low weight, the fiber is impressively strong and resistant to stretching and abrasion. It resists staining, withstands exposure to chemicals, and retains its shape and color even after repeated washing. These attributes make it ideal not only for performance apparel but also for items like socks, underwear, industrial uniforms, and nonwoven fabrics used in medical and hygiene products.

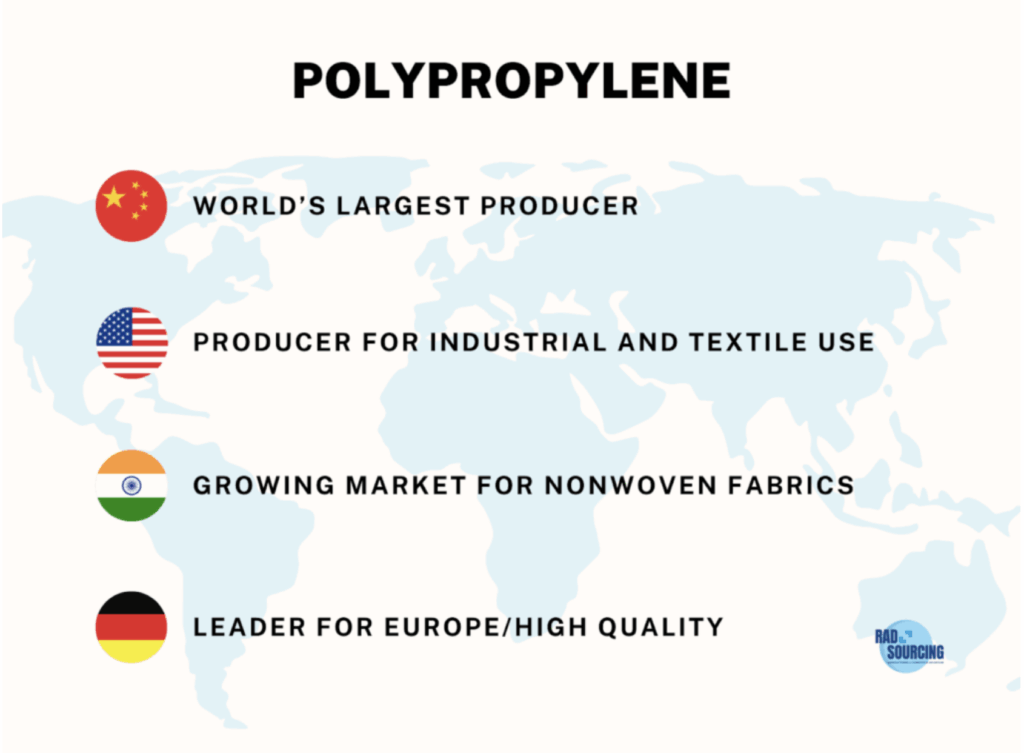

The production of polypropylene begins with propylene gas, a byproduct of petroleum refining and natural gas processing. This gas undergoes polymerization, a chemical reaction that transforms it into a resin. The resulting polypropylene resin is cooled, cut into pellets, and then melted for extrusion. In melt spinning, the melted resin is forced through spinnerets to form continuous filaments. These filaments are then drawn to enhance their strength and, if needed, crimped for texture. The fibers may be used as continuous filaments or cut into shorter lengths (staple fibers) for blending or further processing. Today, polypropylene textiles are predominantly produced in China, India, and the United States, with additional manufacturing hubs across Europe, particularly in Germany and Italy.

While polypropylene is lauded for its performance, its environmental footprint presents a more complex picture. On the positive side, it has a relatively low energy requirement for production compared to other synthetic fibers and does not require water-intensive dyeing processes thanks to solution dyeing methods. It is also recyclable under category #5 plastic, though the infrastructure for textile recycling remains limited. However, polypropylene is derived from fossil fuels, is not biodegradable, and can contribute to microplastic pollution when garments are washed. Although the fiber’s environmental degradation takes hundreds of years, efforts are being made to reduce its impact. Research into bio-based alternatives and circular textile systems is underway, and some brands are beginning to explore closed-loop recycling for polypropylene garments.

In terms of applications, polypropylene is remarkably versatile. Its ability to wick moisture, resist stains, and dry quickly makes it a favorite in athletic wear and performance base layers. Its softness and hypoallergenic nature make it suitable for underwear and baby products. The nonwoven variant of polypropylene is ubiquitous in reusable grocery bags, medical masks, diaper linings, and disposable gowns. Additionally, it is used in geotextiles, carpeting, and outdoor furniture due to its resistance to mildew and UV exposure.

Polypropylene may not be the most luxurious of fibers, but its functionality, cost-efficiency, and adaptability ensure its continued relevance in an increasingly performance-driven textile industry.