Twill is one of the three fundamental textile weaves, distinguished by its characteristic diagonal rib pattern that gives the fabric both strength and visual texture. Known for its durability, flexibility, and drape, twill is one of the most widely used textile weaves, forming the foundation for materials like denim, gabardine, chino, and serge. From rugged workwear to fine suiting, twill’s balance of toughness and refinement has made it a cornerstone of both functional and luxury fabric design.

The origins of twill weaving can be traced back thousands of years to ancient civilizations, including China, Egypt, and Peru, where early weavers discovered that offsetting the interlacing of warp and weft threads produced a strong, diagonal structure. By the Middle Ages, twill was well established in Europe, valued for its strength and smooth surface, making it ideal for outerwear, upholstery, and uniforms. The invention of mechanical looms in the 18th and 19th centuries accelerated the production of twill, and it soon became synonymous with industrial fabrics like denim, the workhorse of modern apparel.

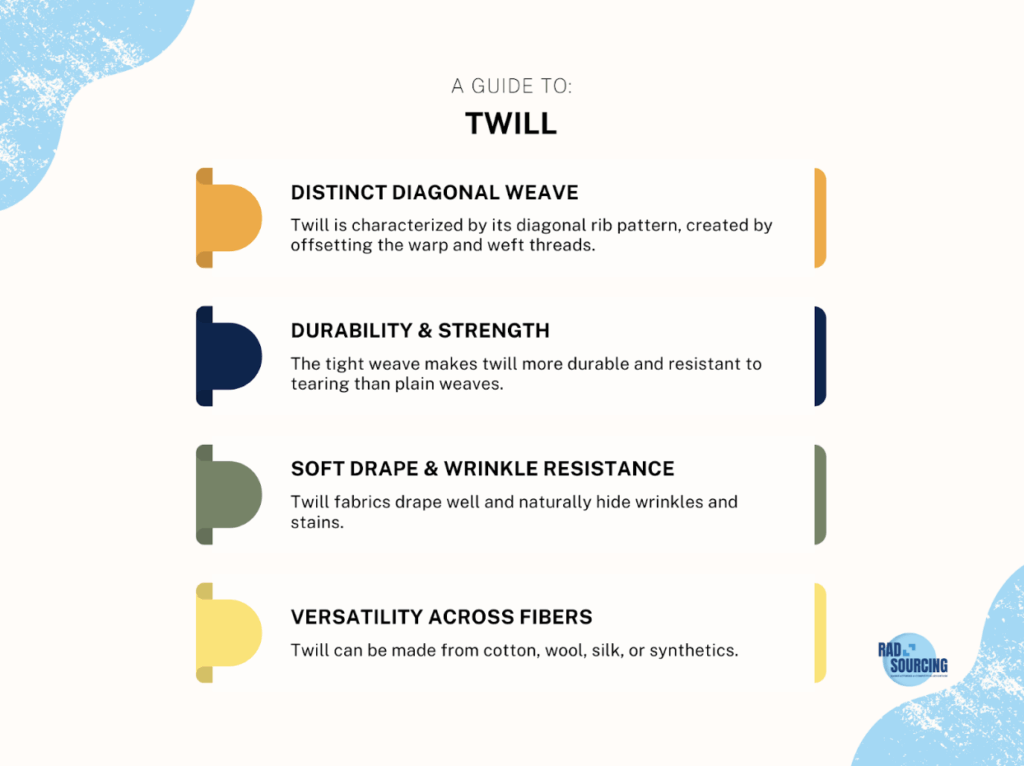

The defining feature of twill fabric is its weave structure. Unlike plain weave, where each weft thread passes over and under alternating warp threads, twill weave involves the weft passing over one or more warp threads and under two or more others, with each successive row offset by one thread. This creates a distinctive diagonal line, or “wale,” visible on the fabric’s surface. Common variations include 2/1 twill, 3/1 twill, and herringbone (a mirrored twill pattern). The result is a textile that is dense, soft, and drapable, with excellent resistance to wrinkles and wear.

The properties of twill fabric make it versatile and durable:

- Strength: The dense interlacing of twill gives it superior tensile strength compared to plain weaves.

- Drape: Twill fabrics fall more fluidly, making them suitable for garments that require shape and flow.

- Wrinkle Resistance: The diagonal structure hides creases and dirt better than smooth weaves.

- Texture and Appearance: The signature diagonal ribs create visual depth and enhance the richness of color.

- Durability: Twill resists tearing and fraying, making it ideal for heavy-duty and long-wear applications.

Twill can be made from nearly any fiber, cotton, wool, silk, polyester, or blends, and can be woven tightly for formal fabrics or loosely for casual ones. For example, cotton twill is used in chinos and workwear, while wool twill forms the base of suiting materials like serge and worsted wool. Silk twill offers a glossy, fluid drape perfect for scarves and ties, while synthetic twills provide durability and weather resistance for outerwear.

In fashion and textiles, twill’s adaptability has made it indispensable.

- Denim: Perhaps the most famous twill fabric, made from cotton in a 3/1 weave with a diagonal texture that defines jeans.

- Chino: A lightweight cotton twill used for trousers and uniforms.

- Gabardine: A tightly woven wool or cotton twill with a smooth surface, popularized by Burberry for trench coats.

- Herringbone and Houndstooth: Variations of twill that use reversing or alternating patterns for decorative effects in suiting.

- Beyond apparel, twill is used in upholstery, curtains, and industrial applications that require strength and drape.

From a sustainability perspective, twill’s environmental impact depends on its fiber content and dyeing processes rather than the weave itself. Cotton twills, for instance, can be highly sustainable when made from organic or recycled cotton and dyed using low-impact methods. Wool twills are renewable and biodegradable, while synthetic twills (polyester or nylon) offer durability but can contribute to microplastic pollution. The weave’s density, however, contributes to longevity, meaning twill garments often outlast plain-weave equivalents, reducing overall consumption and waste.

The global production of twill fabrics spans across textile hubs like China, India, Italy, Turkey, and Japan, each specializing in different fibers and qualities. Italy and Japan are renowned for their high-end wool and silk twills, which are used in luxury fashion, while China and India dominate production of cotton twills and denim. Technological innovations, such as air-jet looms and eco-friendly dyeing, have further refined the quality and sustainability profile of twill.

Twill remains one of the most enduring and versatile weaves in textile history, a perfect marriage of form and function. Its diagonal ribs provide beauty and strength, its adaptability spans casual and formal wear, and its longevity supports sustainable fashion principles. Whether in the timeless lines of a denim jean or the sleek finish of a tailored suit, twill continues to exemplify how thoughtful weaving transforms simple fibers into fabrics of lasting value and character.