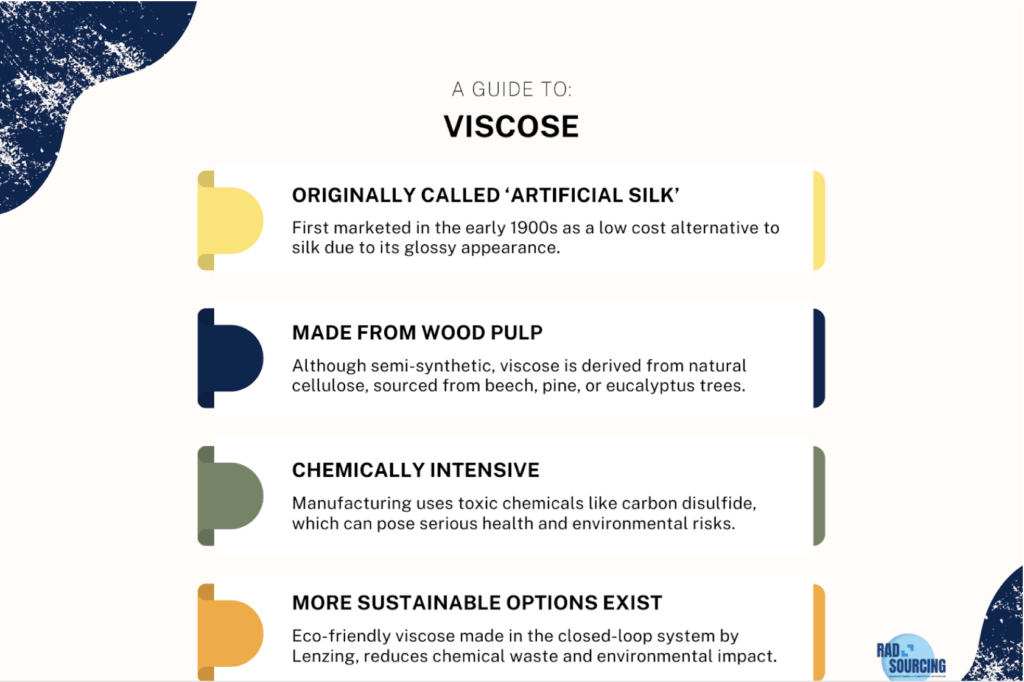

Viscose is a semi-synthetic fiber with a long, evolving history dating back to the late 19th century. Originally developed as an alternative to silk, viscose is made from cellulose, a natural polymer found in plant materials, such as wood pulp. In 1891, British chemists Charles Frederick Cross, Edward John Bevan, and Clayton Beadle patented the process of making cellulose xanthate, which formed the basis of viscose rayon. By the early 1900s, it was commercialized and widely marketed as “artificial silk” before eventually becoming known as rayon in the United States and viscose in Europe.

The key appeal of viscose lies in its ability to replicate the feel and drape of natural fibers, such as cotton, wool, or silk. It is soft to the touch, breathable, and highly absorbent, which makes it especially popular for summer clothing, linings, and flowing dresses. Because it is made from a natural origin (wood pulp) but undergoes heavy chemical processing, it occupies a gray zone between natural and synthetic fibers.

The viscose manufacturing process is chemically intensive and involves several stages. First, wood pulp, typically derived from fast-growing trees such as beech, pine, or eucalyptus, is treated with sodium hydroxide to create alkali cellulose. This substance is then aged and mixed with carbon disulfide to form cellulose xanthate. The resulting orange-colored viscous liquid is dissolved in more sodium hydroxide, filtered, and then forced through spinnerets into a bath of sulfuric acid and other salts, where it solidifies into fibers. These fibers are then washed, bleached, and dried before being spun into yarn.

Major production facilities are located in countries like China, India, Indonesia, and several European nations. Due to the need for raw cellulose and access to chemical infrastructure, the industry tends to be concentrated in regions with robust forestry or chemical sectors.

Sustainability is a key concern in the production of viscose. Traditional manufacturing methods often use toxic chemicals, such as carbon disulfide, that pose significant risks to workers and the environment. Improperly managed facilities may discharge hazardous waste into surrounding ecosystems, posing a significant environmental risk. However, advances in production technologies have led to the emergence of more sustainable viscose options. Companies like Lenzing AG have developed closed-loop production processes that recover and reuse chemicals, significantly reducing environmental impact. Certified sustainable viscose also requires the use of responsibly sourced wood, which is often verified by organizations such as the Forest Stewardship Council (FSC).

Compared to synthetic fibers like polyester, viscose has a smaller microplastic footprint and is biodegradable under the right conditions. However, it is still energy- and resource-intensive to produce, and not all viscose is created equal. Consumers are increasingly encouraged to seek out sustainably labeled viscose, such as those marked with the EU Ecolabel or certified by CanopyStyle and OEKO-TEX.

In practical terms, viscose is a versatile textile used in a wide range of garments and home furnishings. It appears in blouses, dresses, linings, trousers, and even underwear due to its softness and fluid drape. In home goods, it is commonly found in curtains, upholstery, and bedding blends. It dyes easily, holds vibrant colors, and feels cool against the skin, making it especially suitable for warm climates.

While it began as a humble silk substitute, viscose has become a staple in the global fashion and textile industries. With increasing pressure on the industry to adopt safer and cleaner practices, the story of viscose continues to evolve, offering a compelling example of how tradition and innovation can shape the future of sustainable fashion.